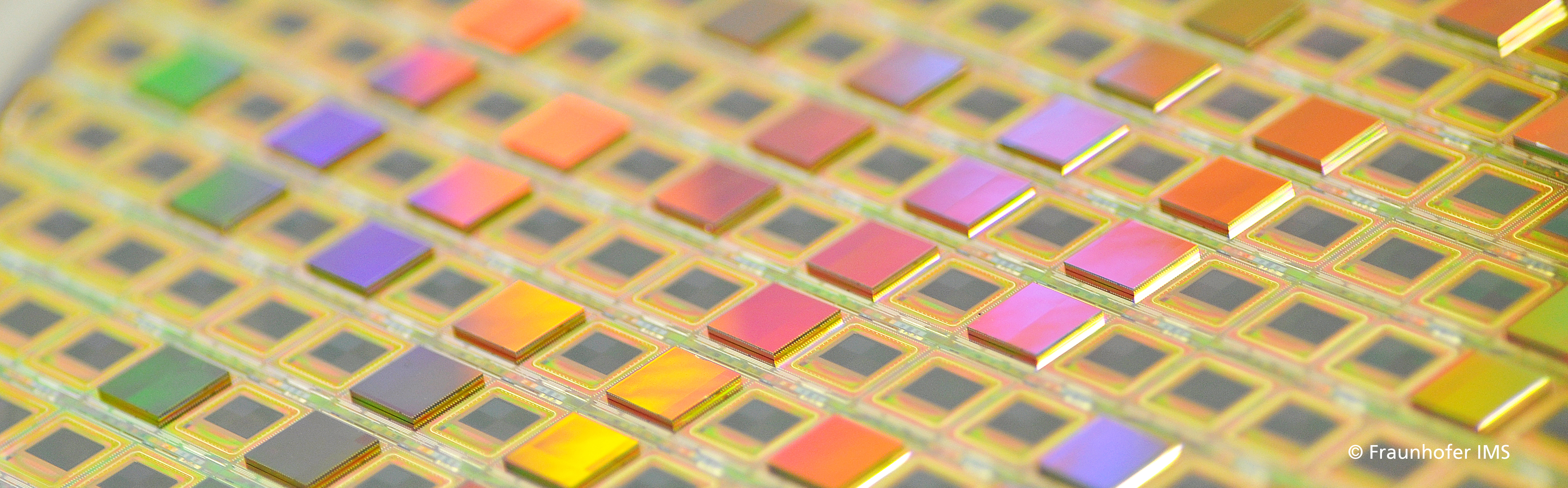

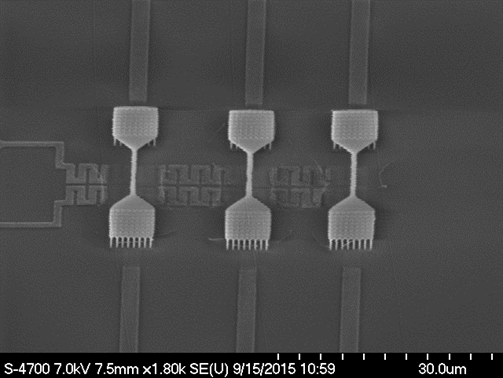

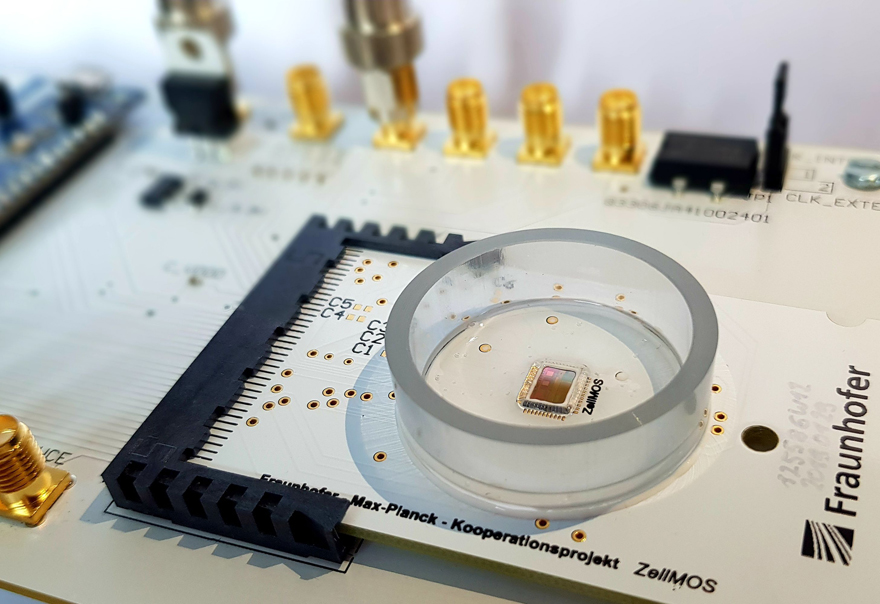

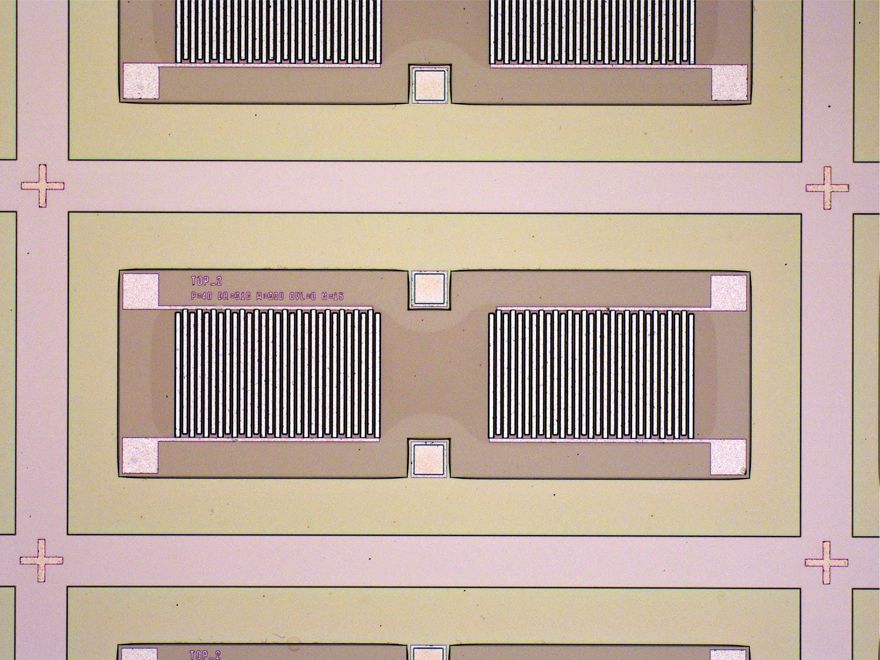

During the last decades the research and development activities in micro- and nanoelectronics led to a continuous reduction in structure size and therefore to an increasingly growing integration density. The goal is always to further increase the functionality on a chip or a microsystem.

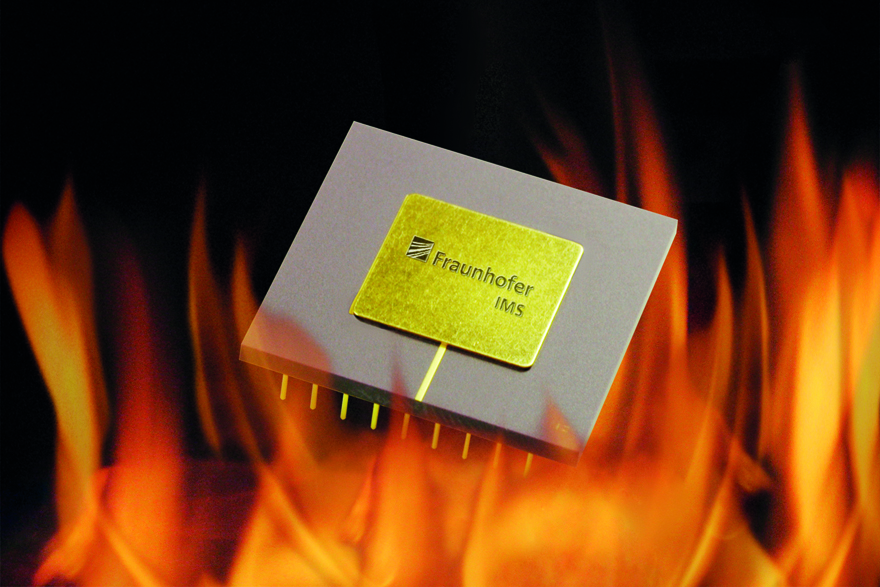

Fraunhofer IMS continues this trend and develops compact and efficient micro- and nanosystems in various application areas: