Intelligent cell-implants get into immediate contact with the nervous system

Intelligent, long-term stable cellular implants that have immediate contact with the nervous system: Working on this innovation is the Fraunhofer-Institute for Microelectronic Circuits and Systems IMS in Duisburg together with the Max-Planck-Institute for medical research and the Institute for neurobiology of the university Heidelberg. Application of this new procedure should be found in medicine. In the long term, the therapy of nerve injuries or the simulation of nerves for example within implants is considered.

These new developments could also be used for eye implants as an electronic interface for prosthesis or for active implants that submit medicines. Another long-term objective is the basic research for better understanding of the interaction of cancer cells. The university around Dr. Amin Rustom plans to examine the communication and interaction of brain cells.

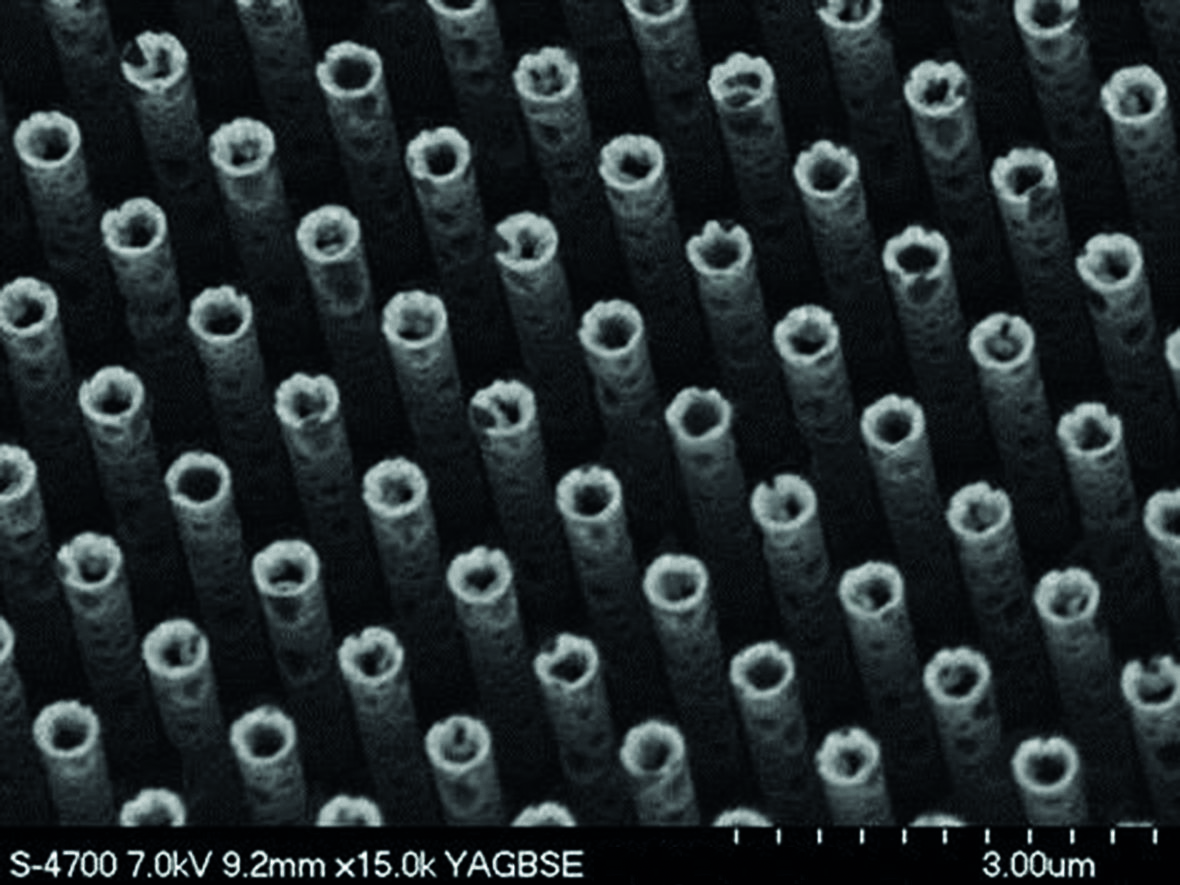

Basis of this new project is a patent of the Max Planck Society of Prof. Joachim Spatz and Dr. Amin Rustom: therefore cells can build a long-term stable contact, if an electronic connection communicates with 3-D electrodes with a special geometry. In doing so, the electrodes penetrate the cell walls without the advocacy of a cytotoxic effect. The actual penetration into the cell has been proven with the help of microscopic technologies.

Now the Fraunhofer IMS is going to contribute a new technology that integrates the 3-D electrodes onto a metal-oxide semiconductor (CMOS). What is new about it? “New is the monolithic integration on only one wafer-plate as a base, which contains the CMOS read-out and control circuit, the “intelligence” is in there. This is a major progress“, explains Dr. Andreas Goehlich, leader of the department CMOS- and microsystem technology.

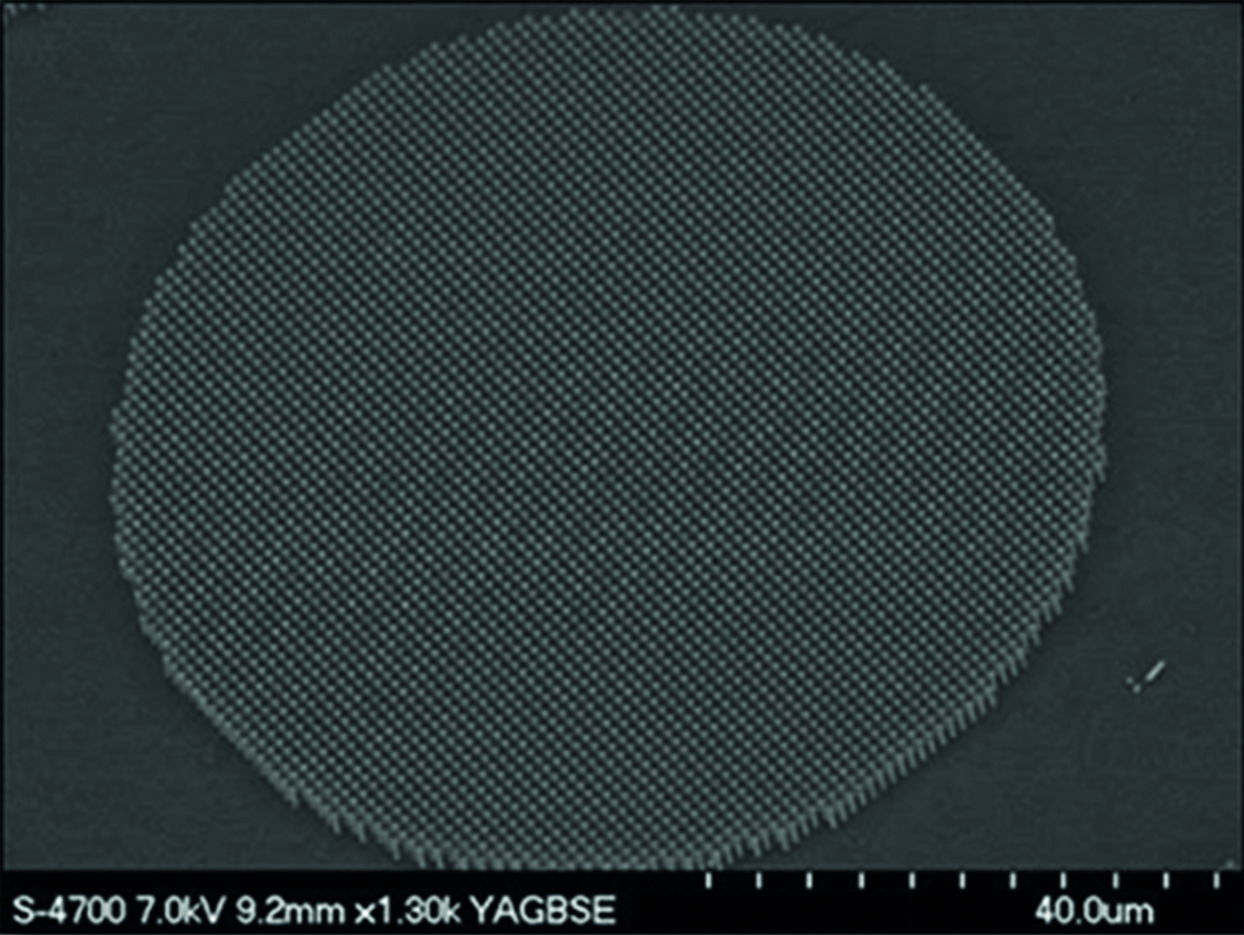

The electrodes are built as really thin needles, for example out of ruthenium in sacrificial-layer technology. Here the contour of the needle is going to be “negatively” etched into a sacrificial layer and then the etched structures are filled with a metallic layer. After the removal of the sacrificial layer a freestanding needle can be received. In the diameter they are smaller than 200 nanometers and a few micrometers long. In experiments, the Fraunhofer IMS is going to optimize the needle structure and even other forms (e.g. fungal forms) are going to be tested. The aim is to increase the longevity of the electronic coupling.

The electronic coupling can happen bidirectional. That means: “Either the nerves provide a voltage signal and we read it out”, explains Dr. Andreas Goehlich, “or we stimulate the cells”. While the electrodes at Max-Planck-Institute are built in laboratory scale, the Fraunhofer IMS wants to take a step towards the application: with professional equipment for the series production on large 200-mm-wafer plates. The Fraunhofer IMS wants to make the technologies also for medium-sized medicine companies available at a cost-effective price. The three-year project started in the beginning of 2016.

The Fraunhofer Institute of Microelectronic Circuits and Systems IMS

Since 30 years scientists at Fraunhofer IMS in Duisburg deal with the development of microelectronic circuits, electronic systems, microsystems and sensors. Because of its comprehensive know-how, the access to technology and the high-quality development work the Institute is a worldwide recognized partner for the industry. In eight business units Fraunhofer IMS is dedicated to applied research, advance development for products and their applications. Stable, efficient and marketable technologies and procedures that are used in extremely many branches take center stage in contract work.