Sensor-readout at the highest level

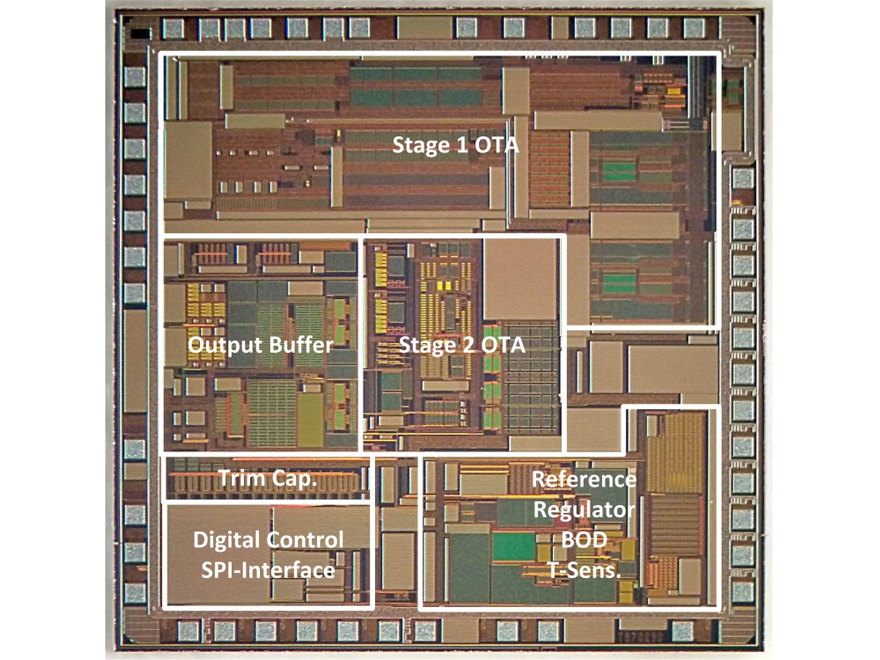

Fraunhofer IMS developed highly-precise sensor-readout-ASICs for robust application. High-precision, robust and secure – regarding sensors, these characteristics seem to contradict. Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg has again performed an important step for the secure implementing of industry 4.0 and developed two sensor-ASIC series for capacitive and inductive sensor readout that do combine these attributes.

Besides a high basic accuracy sensors progressively require robustness under adverse affairs and an increased safety of data. Until now, these three characteristics were difficult to economically combine. The new developed sensor readout ASICs of Fraunhofer IMS, which are intended for the capacitive and inductive sensor readout, enable this now. “Our ASICs always provide an extreme accuracy. The circuit implementation of the new sensor technology is also more robust towards external influences like for example temperature or operating voltage fluctuations. Moreover, it

has got extensive security features and items that are directly obscured on hardware level”, explains Rainer Kokozinski of Fraunhofer IMS.

Safe and space-saving

For an increased security towards hacker attacks novel structures have been developed, that form integrated and uncopiable key memories. “This security function is especially

of importance for the guarantee of data security and the protection of unauthorized access or modification in industrial environment”, says Rainer Kokozinski. Through the hedge directly on the hardware level result substantial advantages regarding security and performance in comparison to already existing solutions. Because of the direct embedment in ICs results for example no additional space requirement.Simultaneously the monitoring of components and – if necessary – a fault analysis of system level is strongly simplified.

Diverse application possibilities

The application fields of the new sensor technology are diverse. Inductive readout-ASICs can be applied for example in solid-state position sensor technology. Because the procedure gets along without magnets it only needs printed inductors as well as a metallic target. This does not only make them cost-effective, but especially robust. The capacitive sensor readout-ASICs are easily adapted to a variety of sensors. Especially, if measurement data of the highest accuracy is required, but only a weak signal is available, they develop their potential. Then they can be applied in for example accelerometers. Thereby they are able to help in seismic measurements for early earthquake detection or can be applied in condition monitoring in the field “Predictive

Maintenance”.

Fraunhofer IMS

For over 30 years scientists at Fraunhofer IMS in Duisburg have been dealing with the development of

microelectronic circuits, electronic systems, microsystems and sensors. Because of its

comprehensive know-how, the access to technology and the high-quality development

work the Institute is a worldwide recognized partner for the industry. In eight business

units Fraunhofer IMS is dedicated to applied research, advance development for products

and their applications. Stable, efficient and marketable technologies and procedures that

are used in extremely many branches take center stage in contract work.

www.ims.fraunhofer.de