The development of CMOS and MEMS based sensor technologies opens up the possibilities for state-of-the-art smart sensor systems for science, industry, medicine, and aerospace. Our technologies for optical sensors cover the spectrum from X-rays to UV and far-infrared. We offer biomedical applications with technologies for pressure sensors, nanoneedles for cell contacting and CarboNanoTube-based bionano-sensors for the identification and detection of biomolecules. In order to offer the optimal solution in each case, we rely both on fully integrated sensor technologies and on the integration of our sensor technologies as postprocessing with foundry technologies.

Core Competence Technology

In the field of image sensors, special optical components such as single photon-avalanche diodes (SPADs), silicon photomultipliers (SiPM) and charge coupled devices (CCDs) are being developed. With BSI technology, back-side-illuminated image and LiDAR sensors can be realized, resulting in improved image quality, higher light sensitivity of the optical sensor and significantly smaller chip size.

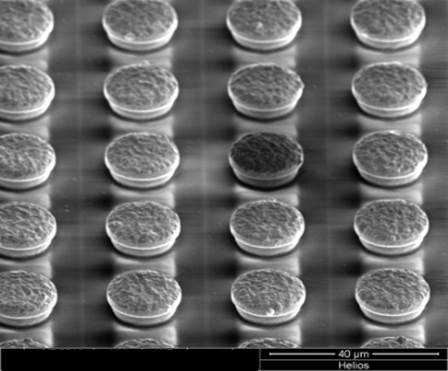

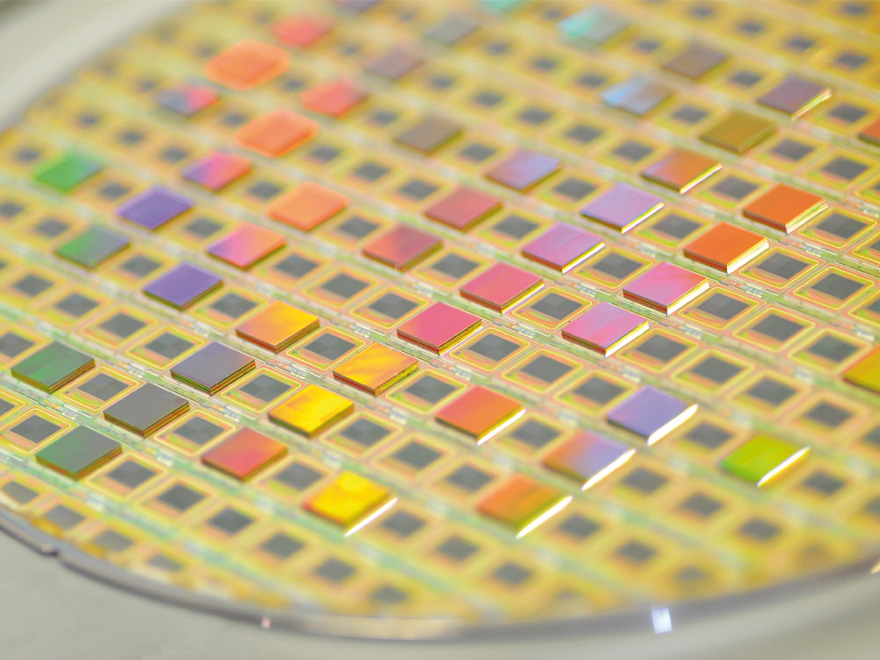

To extend the possibilities of established CMOS technologies, Fraunhofer IMS offers post-processing technologies for the fabrication of MEMS (Micro-Electro-Mechanical Systems) devices and systems for various sensors and actuators. Post-processing enables the integration of new materials and micromechanical structures. Here, CMOS wafers serve as an "intelligent" substrate, as they already contain drive and readout circuits, signal processing and interfaces for energy transfer. Planarized CMOS circuit wafers can be further processed for the fabrication of new innovative MEMS systems by means of layer deposition and patterning in the Microsystems Technology Lab&Fab. These new systems can be, for example, pressure sensors or microbolometers with integrated readout electronics. The combination of CMOS and MEMS results in cost-effective and extremely compact microsystems for use in medicine, industry, mobility and even aerospace.

In order to continue the trend of microelectronics towards - faster, more compact, more powerful and cost efficient - Fraunhofer IMS uses different technologies. For example, 3D integration offers the option that by exploiting the third dimension, structures are built on top of each other to achieve shorter interconnect distances, higher integration density and cost reduction. Furthermore, Fraunhofer IMS offers innovative thin film deposition processes based on ALD technology. This allows the fabrication of protective layers, optical coatings, NEMS devices for gas sensors or biosensors with nanowires or nanoneedles as well as ultra-thin free-standing membranes in addition to electrical contacts.

In addition, Fraunhofer IMS technology offers biofunctional sensors for example for the development of highly sensitive nanosensors or infrared sensitive resistors for near infrared detection.

Our special technologies include customized CMOS technologies and also a high-temperature process, which enables the use of circuits under harsh and hot conditions up to 300°C.

In addition to complete technology processes, services such as wafer bonding, electroplating, CVD/ALD, sputtering, etching, lithography, etc. are also offered.