Color sensors for better vision

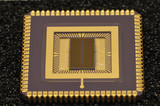

CMOS image sensors in special cameras – as used for driver assistance systems – mostly only provide monochrome images and have a limited sensitivity to light. Thanks to a new production process these sensors can now distinguish color and are much more sensitive to light.

The car of the future will have lots of smart assistants onboard – helping to park the car, recognize traffic signs and to warn the driver of blind spot hazards. Many driver assistance systems incorporate high-tech cameras which have to meet a wide range of requirements. They must be able to withstand high ambient temperatures and be particularly small, light and robust. What’s more, they have to reliably capture all the required images and should cost as little as possible. Nowadays CMOS sensors are used for most in-car systems. These semiconductor chips convert light signals into electrical pulses and are installed in most digital cameras. At present, however, the sensors used for industrial and other special cameras are mostly color blind.

Now researchers at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg are adding some color to the picture. They have developed a new process for producing CMOS image sensors which enables the chips to see color. Normally the image sensors are produced on silicon wafers using a semiconductor technique, the CMOS process. “We have integrated a color filter system in the process,” explains Prof. Dr. Holger Vogt, Deputy Director of the IMS. “In the same way as the human eye needs color-specific cone types, color filters have to be inserted in front of the sensors so that they can distinguish color.” This job is handled by polymers dyed in the primary colors red, green and blue. Each pixel on the sensor is coated with one of the three colors by a machine which coats the sensor disk propels with a micrometer-thick polymer layer. Using UV light and a mask which is only transparent on the desired pixels, the dye is fixed at the requisite points and the rest is then washed off. In addition, the researchers have developed special microlenses which help the sensor to capture and measure the light more efficiently. With the aid of a transparent polyimide they create a separate lens for each individual pixel, which almost doubles the light-sensitivity of the image sensor.

The optimized CMOS process not only makes it possible to cost-efficiently improve the performance of driver assistance systems. Endoscopes can also benefit from the new properties of CMOS image sensors. The researchers are presenting the CMOS process at the Vision trade fair from November 3 to 5 in Stuttgart (Hall 6, Stand 6D12).

Download:

Contact:

Dipl.-Ing. Martin van Ackeren

Phone: +49 203-3783-130

e-mail: martin.van.ackeren(at)ims.fraunhofer.de

Fraunhofer-Institut für Mikroelektronische Schaltungen und Systeme IMS

Finkenstraße 61

47057 Duisburg