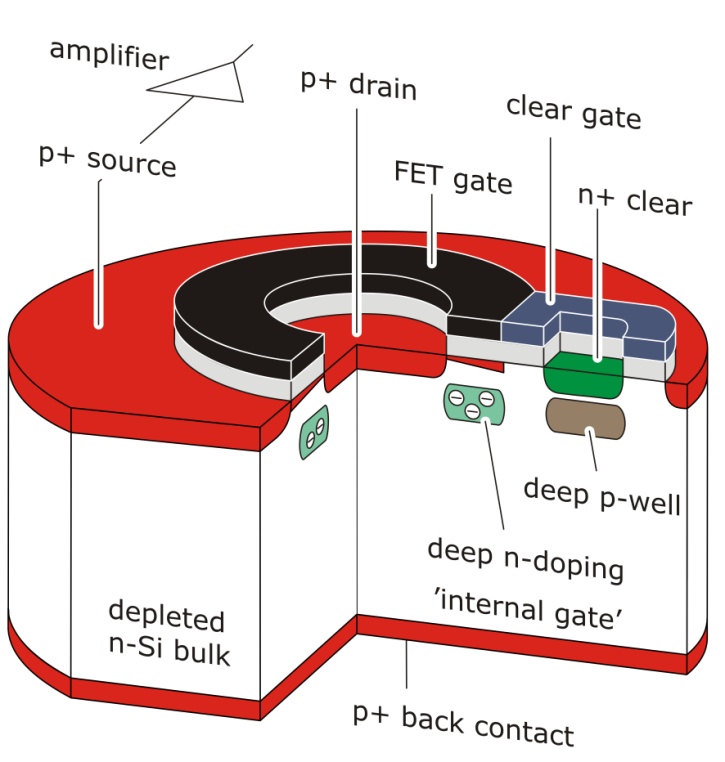

DEPFET detectors (“depleted p-channel field-effect transistor”) are ultra-fast pixel detectors with excellent energy resolution and high radiation hardness. Applications of X-ray sensors and detectors with integrated electronics range from fundamental and applied research to industrial analytics and quality inspection.

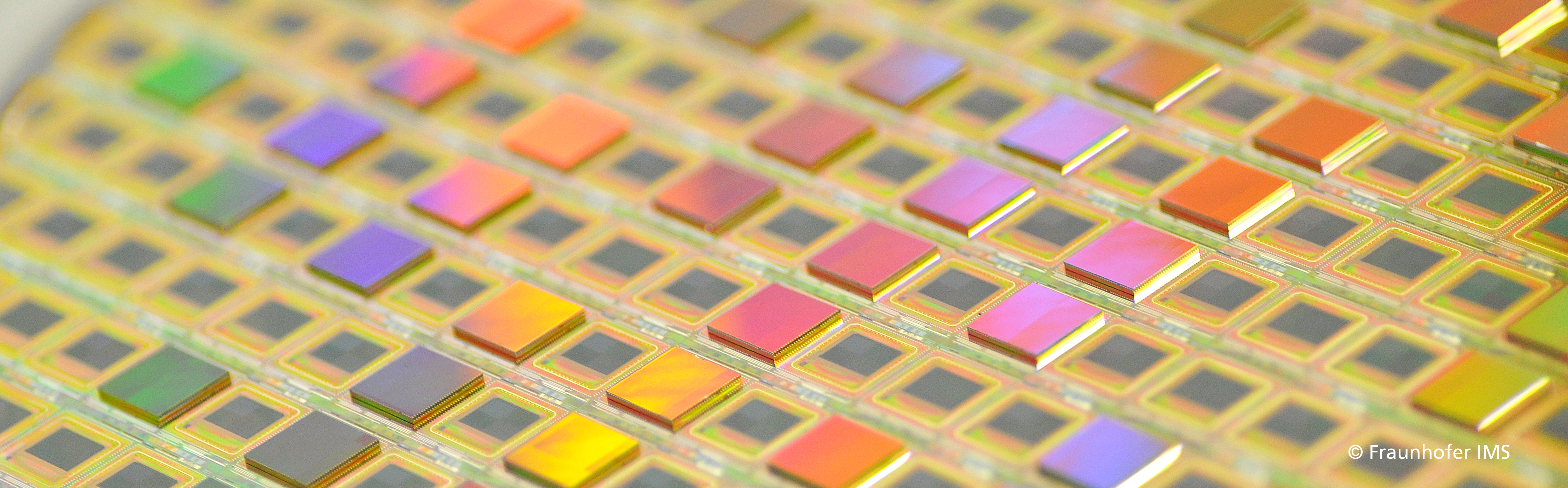

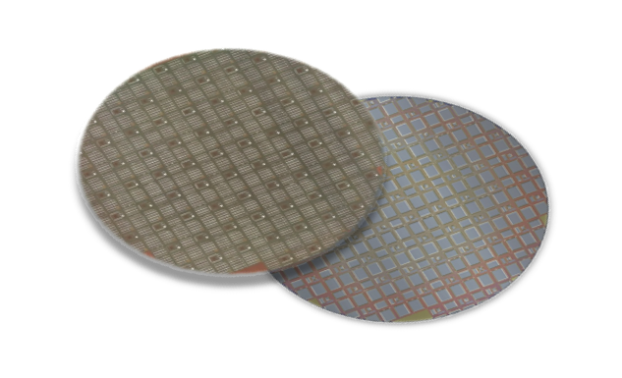

A DEPFET pixel consists of a field-effect transistor on a fully depleted substrate. With the first stage of signal amplification integrated in each pixel, DEPFET detectors provide low input capacitance and excellent signal-to-noise ratio. In the past these special sensors have been fabricated only in research labs. Together with PNSensor, Fraunhofer IMS is developing a fabrication process with industry quality standards.

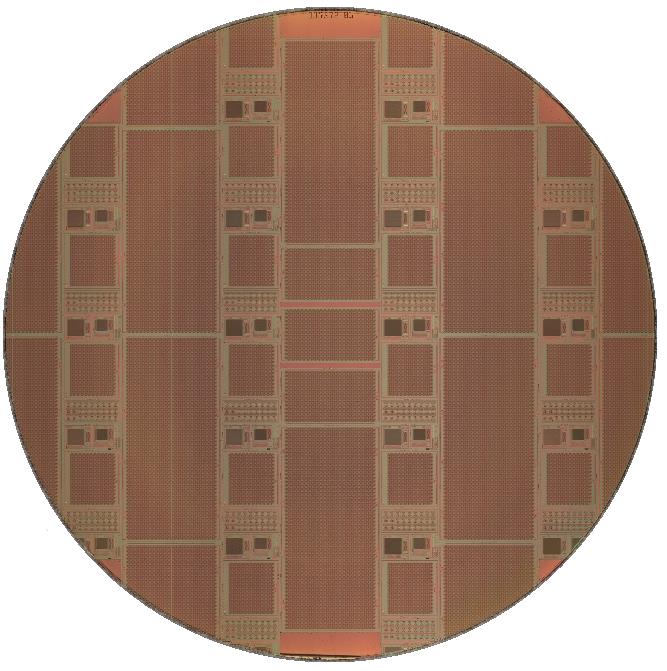

For the application as detectors at a free-electron laser, large-area detectors with an active area of 18 cm² are currently being developed. In contrast to other BSI sensors, backside illumination of the DEPFET detectors is realized by double-sided wafer processing. Due to the large chip area of the detectors, a so-called stitching process is used where multiple layout pieces are seamlessly pieced together to one single detector chip.

The fabrication of DEPFET detectors within a CMOS line offers high process stability at short turn-around times and reduced cost. Furthermore CMOS processing offers new design options to detector developers. This enables improved detection and amplification characteristics and opens new applications in fundamental and applied research.