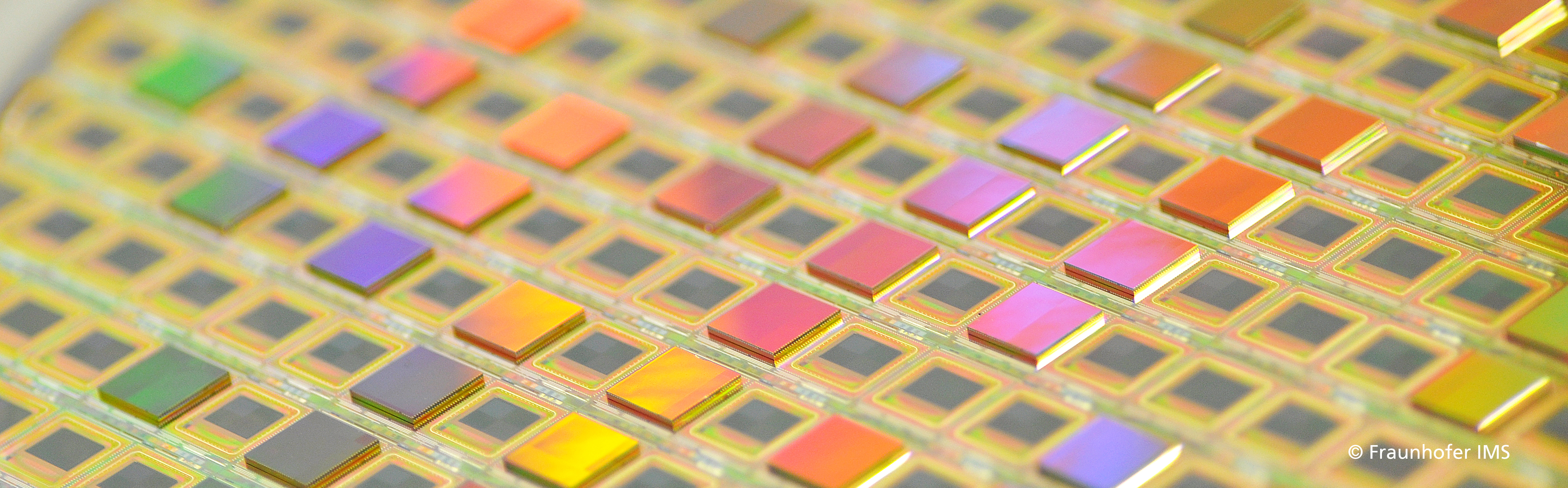

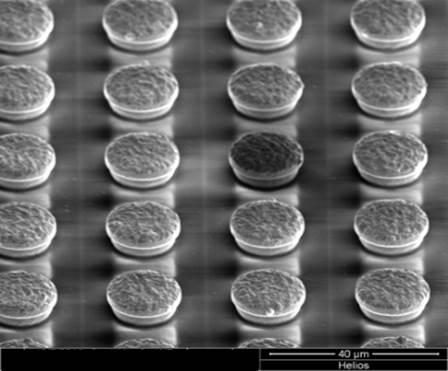

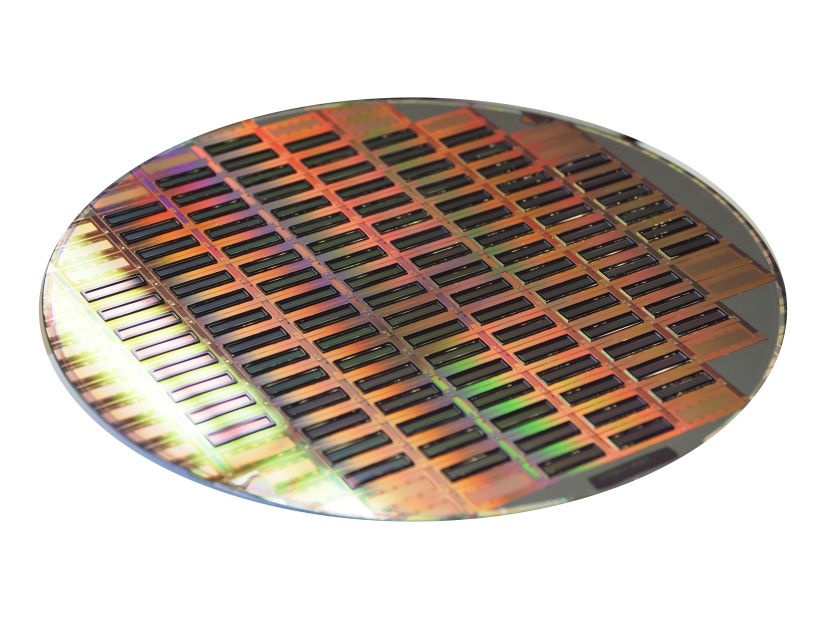

Use our services and the know-how of the Fraunhofer IMS in the fields CMOS and microsystems technology for the development of innovative and compact microsystems.

The Fraunhofer IMS can rely on 30 years of experience in the area of CMOS technology development and has been focusing especially following areas: