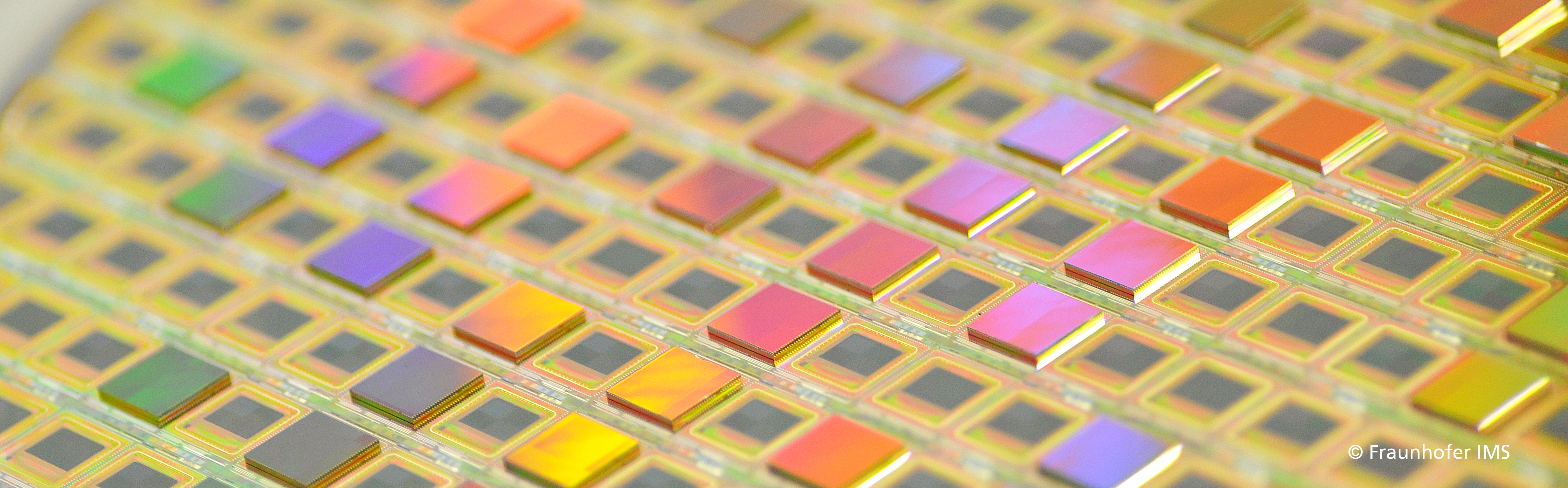

Infrastructure CMOS Fab

For the realization of customer-specific technologies and mixed-signal ICs a fully equipped, professionally operated 200 mm CMOS clean room with different robust 0.35 µm-CMOS technologies is available. High-voltage SOI-CMOS, high-temperature SOI-CMOS and 0.35 µm automotive mixed-signal CMOS are based on IMS CMOS-process technologies. The whole infrastructure is designed for the high requirements of the automotive industry and reaches the corresponding automotive industrial standard. Even realizations of special steps, e. g. surface planarizations, are possible in the CMOS clean room.

Characteristics of the CMOS Fab

- Focus: Customer-specific CMOS processes

- Area: 1,300 m2

- Minimal structure size: 0.35 µm

- Personnel: 4 shifts / 7 days a week

- Capacity: >50000 wafer per year

- Core competencies: highly qualified CMOS technologies

- Mixed-signal ASICs

- High-temperature SOI-CMOS

- Imagers

Infrastructure microsystems technology Lab&Fab

For further processing of 200 mm CMOS or customer wafers a microsystems technical clean room has been built with support of the State of NRW, the BMBF and the EU. As a competent partner we offer the development of individual process steps over process modules up to the complete MEMS technologies. Especially post-CMOS processes for functionality extensions of CMOS wafers are in focus. On these “intelligent” substrates, equipped with analog and digital control, readout or interface circuits, functional structures are applied in the microsystems technology Lab&Fab. With this combination of CMOS and MEMS innovative and compact microsystems for the application in medicine, industry, automotive, aerospace up to consumer applications can be created.

Characteristics of the microsystem technology Lab&Fab:

Focus: integrated sensor systems on “intelligent” substrates

- Area: 600 m²

- Minimal structure size: 0.35 µm

- Capacity: 5000 wafers per year

- Core competencies: microsystem technology on CMOS

- Pressure sensors

- Biosensors

- Microbolometers

- Backside illuminated sensors

Infrastructure integrated circuit packaging

Apart from the CMOS and MST clean room, Fraunhofer IMS offers a broad spectrum of process steps in the area of back-end processing of microelectronic devices and systems.

Wafers out of the front-end-of-line can be tested, thinned, separated and installed. For special test and mounting requirements in the area of pressure and image sensor systems there are several clean rooms and facilities available.