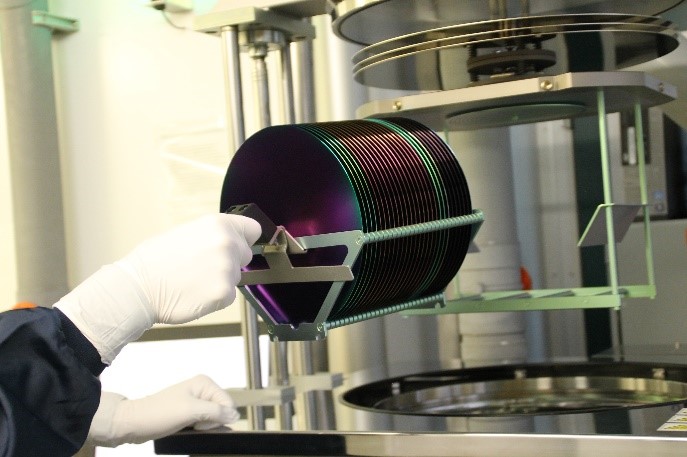

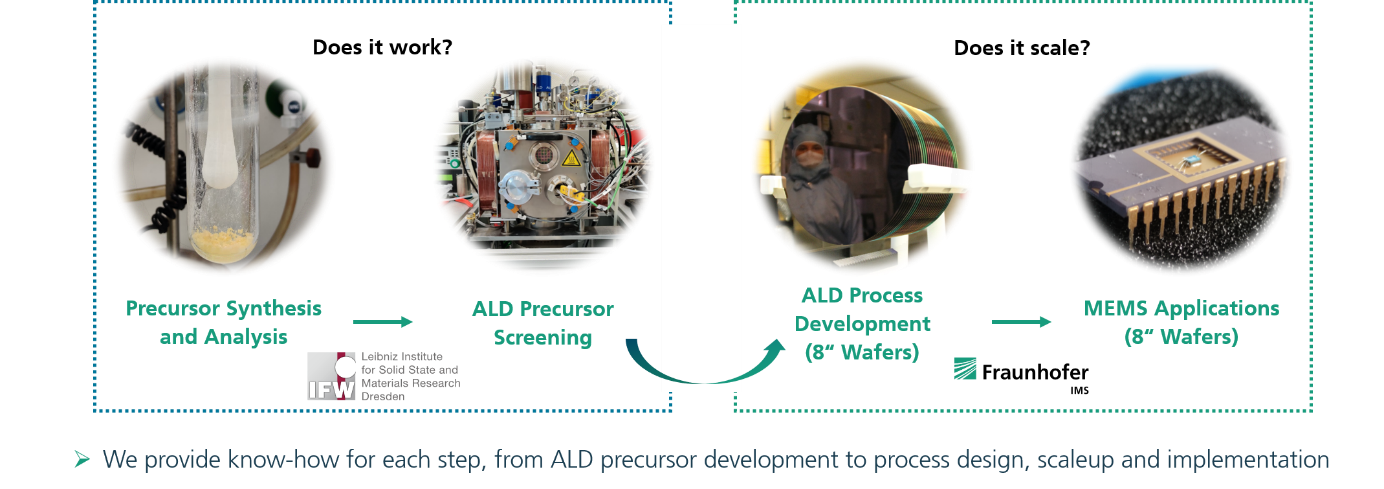

Since the process temperature during ALD deposition is low compared to conventional CVD processes, ALD layers can be deposited particularly well on substrates with integrated circuits, i.e. on CMOS wafers. Thus, ALD technology can be used for various MEMS, NEMS or CMOS-related applications, such as:

- Development of new precursors, processes and materials for molecular sensors, e.g. chemiresistive gas sensors and biosensors with a focus on transition metal dichalcogenides (2D-TMDC) materials such as MoS2 and WS2

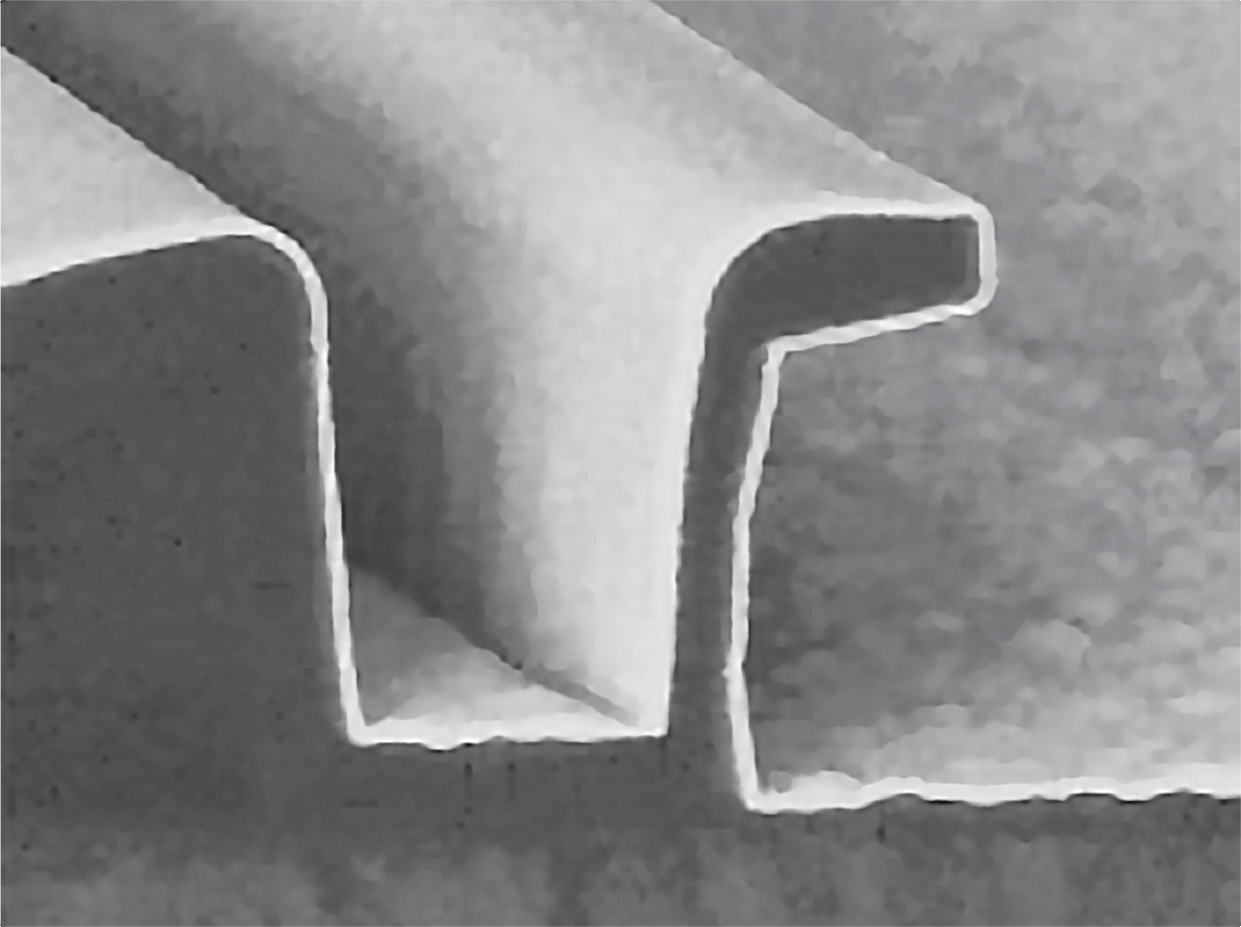

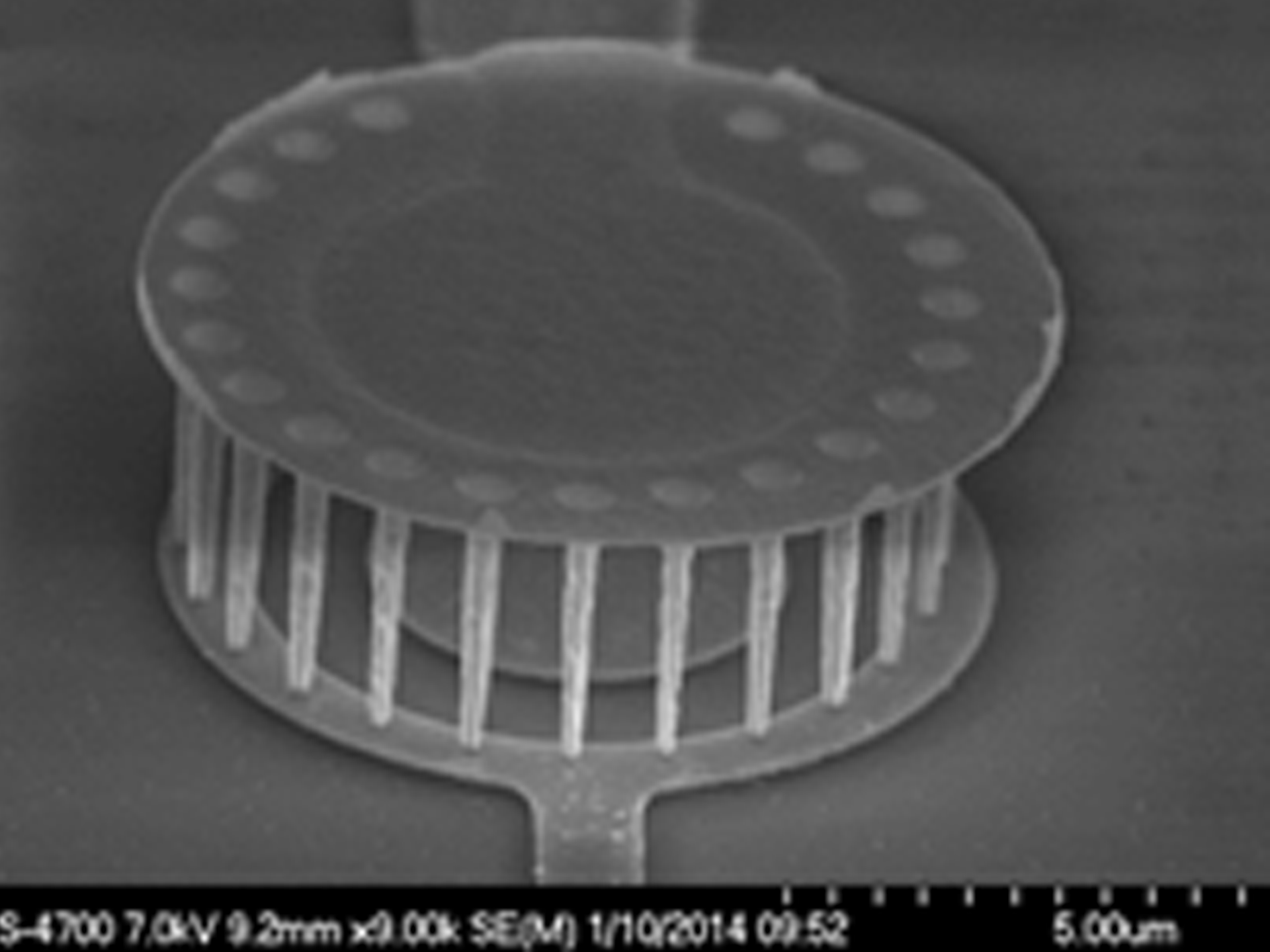

- Cost-effective 3D-NEMS technologies for the generation of free-standing nanostructures on CMOS surfaces with the highest reproducibility have been developed and patented by the Fraunhofer IMS.

- Media-resistant layers for sensor applications such as pressure sensors or for the encapsulation of medical implants. Nanolaminates are available as ALD passivation. Further ALD materials can be implemented at the Fraunhofer IMS upon request.

- Electrical or optical shielding can be produced by metallic layers such as ruthenium (Ru). Furthermore, ALD layers can be used as transparent conductive electrode layers, for example for optical sensors or solar cell applications.