Imaging thermography is the standard application of IR imagers in which the surface temperature of an object is determined contactless and without active lighting by the emitted infrared radiation. The imaging thermography is used in building inspection, where it is utilized for determination and documentation of energy efficiency of the buildings. Moreover, imaging thermography can be used for carrying out inspections of production plants and control cabinets.

Thermography

Thermography as a standard application of IR imagers

Imaging thermography for building inspection

Imaging thermography in building inspection is the large area of application for cost-effective uncooled infrared sensors. To conserve resources, houses are being built or modified more and more energy-efficiently through the use of new insulation technologies. In order to document the energy efficiency of buildings, thermal imaging cameras are used to detect weak points in the insulation. The procedure is also suitable to detect concealed construction elements like mounts in wall constructions in buildings. To identify even the smallest temperature differences in order to detect the small weak points in the insulation, infrared sensors with a particularly good thermal resolution (NETD < 60 mK) must be used. Here, you can see a thermography image of a building with significant temperature differences. The weak points in the insulation are clearly visible.

Imaging thermography for the inspection of systems

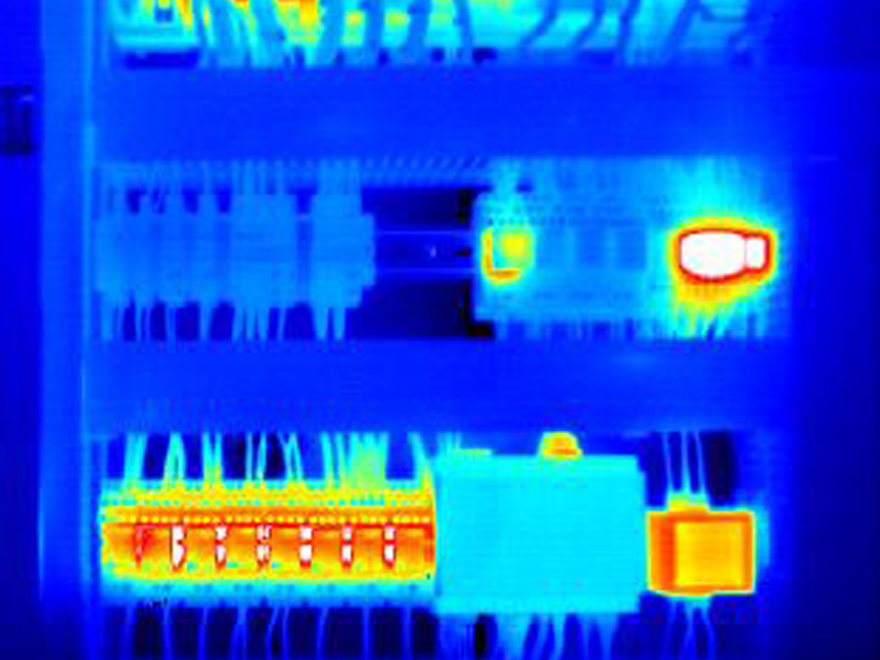

By visualizing the local temperature distribution on devices and components, thermal images enables the detection of faults in systems at an early stage. For example, electronic components or electrical systems can be monitored continuously or periodically by means of imaging thermography. Defective components or connections (e.g. short circuits or high transition resistances) are reliably detected by an atypical temperature signature. Thereby, the cause of the fault can be eliminated before systems fail or suffer irreparable damage.

Contactless inspection using thermal imaging cameras can replace costly manual measuring methods and allows system monitoring that is significantly more efficient and reliable. With continuous monitoring, thermal image data is evaluated directly and automatically and configured in such a way that an alarm is triggered in the event of a deviation. Now, intervention can be taken and the cause of the system error can be rectified, before the system fails.