The imaging gas sensor technology is based on uncooled IR imagers (IRFPAs = infrared focal plane arrays) and enables the contactless and fast detection and localization of gas leaks. Compared to conventional methods, such as gas detectors, large-areas or difficult-to-move areas can be monitored particularly well using an imaging method. Undetected gas leaks not only pose a great danger to people, the environment and plants, but also lead to additional economic losses.

Gas-Sensor technology

Gas sensing as an application of IR imagers

Imaging gas sensor technology using uncooled IR Imagers

Large industrial plants, gas suppliers and also biogas plants use widely branched pipe systems or gas pipelines. There, leaks, e.g. in gas pipelines with methane, CO2 or CO, not only pose a great danger, but also damage the environment and cause economic losses due to the undesired gas leakage. Up to now, gas detection devices or foam-forming aids have been used to detect and localize gas leaks. However, these methods require direct contact with the leakage point and especially the localization of the leakage means a high expenditure of time and personnel.

With the help of imaging gas sensors based on uncooled IR imagers (IRFPAs = infrared focal plane arrays), leaks can be localized contactlessly, quickly and reliably. Imaging techniques make it possible to monitor large areas particularly well, as well as areas that are difficult to access. Mobile cameras or drones can provide a platform for detecting and localizing gas leaks.

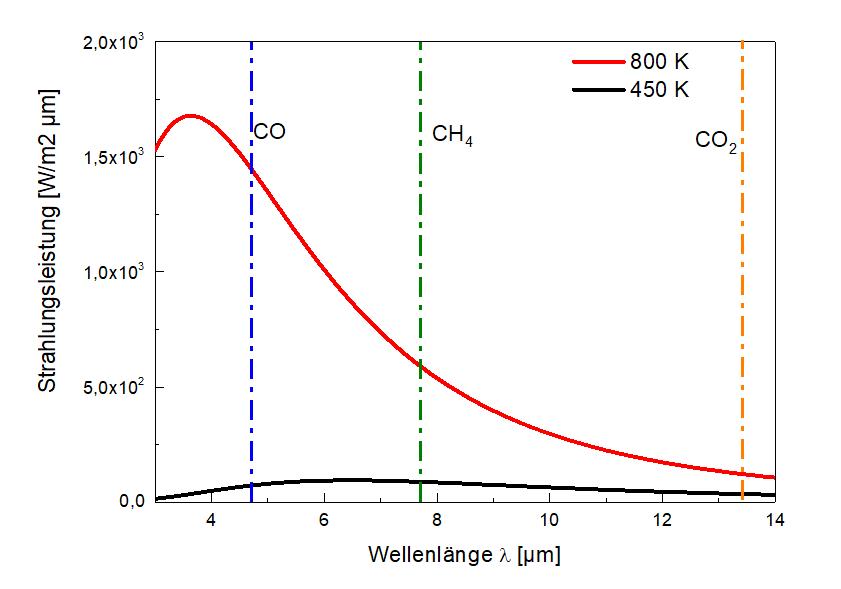

Imaging gas sensor technology exploits absorption in certain wavelength ranges as a specific property of gases. Most technical gases exhibit several differently pronounced absorption lines in the mid-infrared range between 3µm and 5µm. In order to detect these metrologically, the corresponding background radiation must be present in addition to the IR imager. To increase sensitivity, this can be a blackbody radiator with temperatures of 800K or 450K, for example, but the naturally available thermal IR radiation can also be used. In first figure, thermal radiation from blackbody emitters at two temperatures and relevant absorption lines from the example gases CO (carbon monoxide), CH4 (methane) and CO2 (carbon dioxide) are shown.

Significant absorption lines in the IR region are visible for the example gases. With theoretical calculations it could be shown that in combination with a blackbody emitter detection limits of 15ppm - 20ppm for carbon monoxide and methane can be achieved. Further reductions of the detection limits by a factor of 10 can be achieved by averaging over a period of 20s. A measurement period of 20s is typical for commercially available gas sensors.

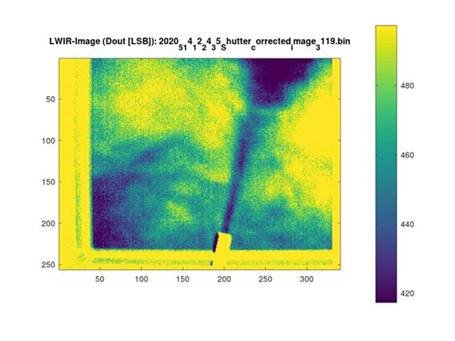

The leakage of carbon dioxide from a hose can be clearly seen. This measurement result was obtained with the standard digital 17µm QVGA-IRFPA of the Fraunhofer IMS. This is actually optimized for applications in the long-wave IR spectral range (wavelength 8µm - 14µm). Currently, Fraunhofer IMS is adapting its IFRPA for maximum sensitivity in the MWIR range. Since the absorption lines of most technical gases lie in this range, the detection of gas leaks will be further improved once the development work is completed.

Even without active emitters, the thermal radiation emitted by every body according to Planck's law can be used. Since this is lower than in the case of an active emitter, higher detection limits result. From theoretical calculations it can be shown that the detection limits of methane without an active emitter are about 1700ppm. This value corresponds to about 4% of the lower explosion limit, which in the case of methane is about 4.4% by volume.

Fraunhofer IMS is currently optimizing its IRFPAs for the mid-infrared range and is looking for partners for applications of this technology. Please do not hesitate to contact us!