Experience in the field of CMOS technology development at Fraunhofer IMS

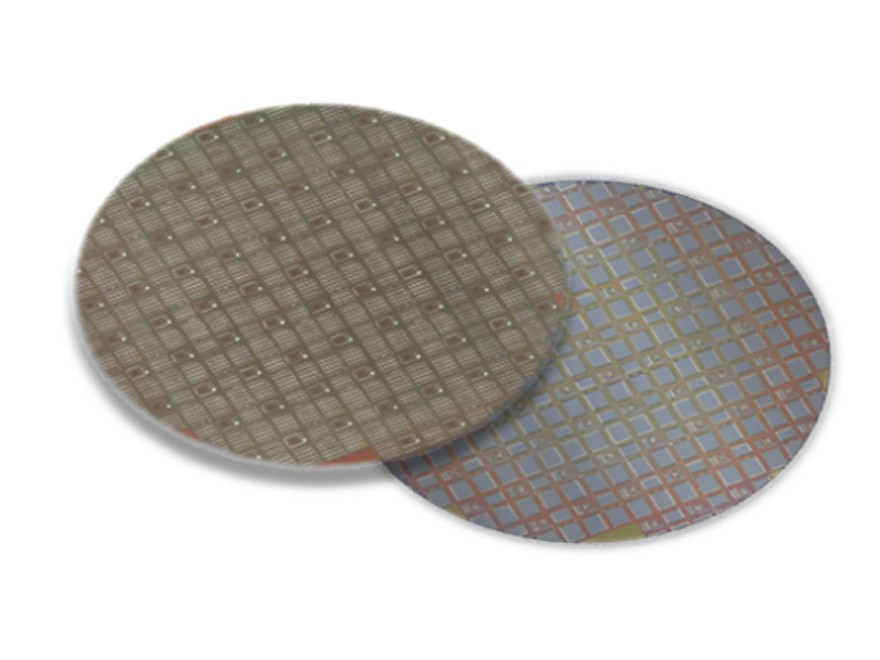

For more than 35 years, Fraunhofer IMS has been engaged in CMOS technology developments and has as its development base a 200 mm CMOS line according to industrial standards with various robust CMOS processes down to a minimum structure size of 0.35µm (Center for Sensor Technology).

The Fraunhofer IMS optimizes CMOS processes in the sense of the "More-than-Moore" principle by integrating additional functions such as high-voltage-resistant components, high-frequency circuits and sensors. Fraunhofer IMS also develops technologies that allow the use of the circuit under harsh conditions.

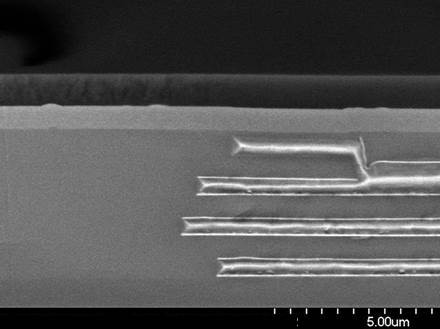

The preparation of CMOS wafers as "smart" substrates by e.g. planarization is also an important development task. On these "intelligent substrates" layers are deposited and patterned by post-CMOS processes and thus new, additional components are realized on the CMOS circuits.