RFID technology has now become firmly established in many areas. To ensure that RFID technology remains a solution for many applications in the future, it is necessary to respond to new challenges that arise and adapt or completely re-new developed solutions. Especially in the field of industry and medicine, high demands exist on the systems and problems are addressed that conventional RFID systems cannot cope with. There is therefore a need for the continuous further development of this technology. In addition to the established frequency ranges LF, HF and UHF, new solutions are emerging that use the SHF band (Super High Frequency) - the so-called SHF-RFID technology.

SHF-RFID

An important part of these SHF RFID systems is the reader. The reader modulates and generates a carrier frequency signal and sends them to an RFID tag. The response is received by the reader, converted to baseband and then interpreted according to the communication protocol. This information is then made available to the application or user.

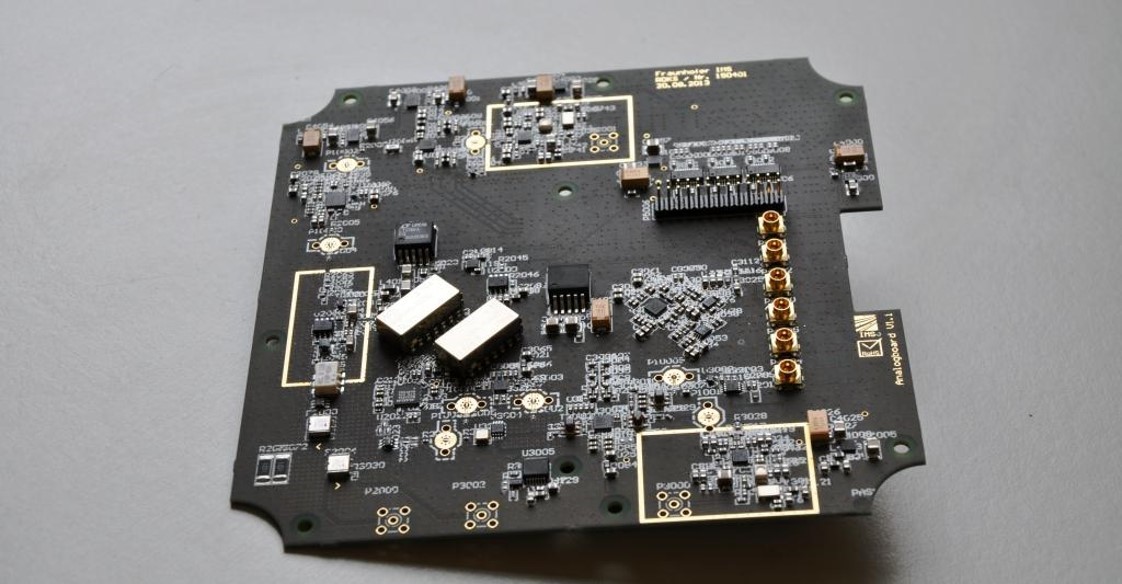

In recent years, Fraunhofer IMS has developed a baseband board that performs signal processing in the baseband based on the ISO 18000-6 EPC Gen 2 standard. Based on this board, a UHF or SHF RFID front-end can be used to modulate the baseband signals to a carrier frequency. The output power as well as the carrier frequency are adjustable.

For interested parties it is possible to set up exact requirements from the application and to select the suitable RFID technology (UHF-RFID or SHF-RFID). Accordingly, a reader is implemented on a modular basis. Supplementary signal processing components such as improved carrier suppression against crosstalk of the transmit signal on the receive path or the mode swirl patented by Fraunhofer IMS for optimal illumination of the target area by the transmit signal can also be used. A combination with our RFID in/on Metal technology is also possible. We can also take over the individual connection via a gateway to your system directly. The result is a reader tailored to your needs.

At the moment we are working on further projects to reduce the size of the reader in order to realize a reader that is as compact as possible. Reference projects are Cute Machining, SteriRob and Prädira.

Application examples

- Tool management: the unique identification of tools such as milling cutters and drills and their individual wear monitoring

- Sterile supply management: the unique identification of surgical instruments and their individual management and tracking in hospital operations.