In production facilities and processes, tool and packaging machines and handling systems are drives for motion/positioning – both linear and rotatory – and corresponding sensor systems omnipresent. The efficiency of production processes concerning precision and speed as well as availability of production facilities are decisively influenced by these actuator and sensor systems. With regards to paradigm shift described by the key word industry 4.0 or digitalization of the industry there are supposed to be extended possibilities in the future to ensure more flexible, fast and reliable processes.

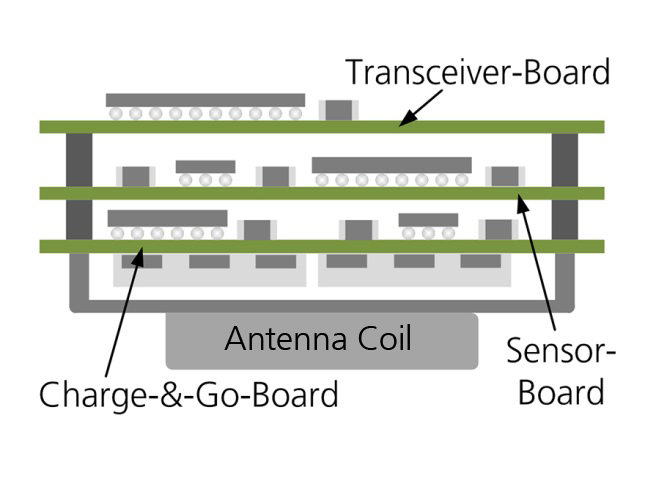

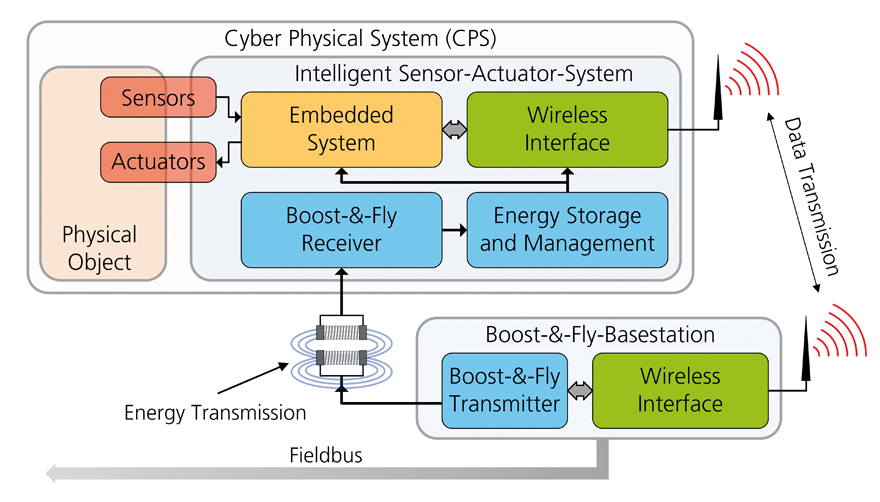

In the project MoSeS-Pro a modular, open sensor system kit for assembly, handling and packaging processes of industry 4.0 are to be realized. Apart from the improvement of the sensor functions, the signal evaluation with regards to condition monitoring applications is to be extended as well. As sensor principles primarily magnetoresistive (XMR) technologies with the main focus on TMR are considered that cover a broad application spectrum (power, angle, path, position). Moreover, self-sensing drives are considered that allow servo control and condition assessment through voltage/power measurement and model-based evaluation. In addition, more sensor principles are integrated in an exemplary way. For the flexible integration in facilities and processes real-time capable radio interfaces and electronics for energy harvesting are to be realized. The MoSes-Pro kit is supposed to be tested with exemplary applications in a laboratory and demonstrated with Festo and Bosch Rexroth (associated partners) in production processes.