In the context of climate protection, the importance of energy efficiency is increasing, as is the share of electricity from renewable energies. Thousands of wind farms, solar modules and biogas plants already generate large quantities of green electricity. The expansion of wind power plants in particular has led to leaps in performance in recent years. The share of renewable energies in EU-wide electricity generation rose to a good 32 percent in 2018. This is shown by the 2018 Annual Report on the European Union's electricity system. However, the larger quantities of green electricity must be fed in, transported and distributed. This requires modern and efficient grids.

Monitoring of Overhead Lines

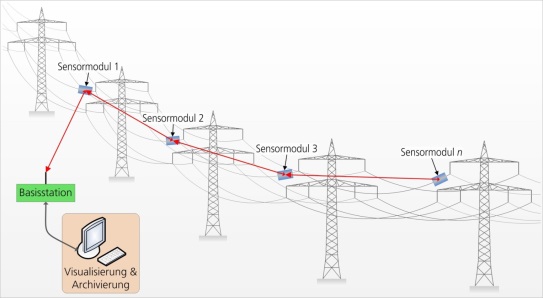

In addition to optimal utilization of overhead lines in grids, the fastest possible detection and localization of dangerous situations such as short circuits or ice cover is an important performance indicator for network operators. This requires a sensor-based acquisition of the operating status with electronic sensor modules, the so-called Condition Monitoring. The sensor modules are installed at equidistant intervals directly on the conductor of an overhead line. The systems currently available on the market are not completely convincing in terms of reliable monitoring of operating parameters. The immature or partially missing infrastructure with regard to area-wide network coverage makes condition monitoring of high-voltage overhead lines even more difficult. An important feature is the autonomous operation of the sensors on the overhead line, which draws its energy from the power of the conductor by means of energy harvesting.

At this point, the Norwegian company Heimdall Power AS and the Fraunhofer IMS started to develop a sensor system, which monitors a multitude of parameters for condition monitoring during operation even under difficult conditions and functions independently through energy harvesting. In addition to monitoring the operating parameters such as

- conductor cable/housing temperature

- conductor current

- conductor inclination

The system also detects short circuits. The collected data is forwarded via the license-free ISM frequency band at 868 MHz to a base station, which sends the data via the mobile network or an existing Ethernet network to a cloud application for further processing.

The sensor modules mounted on the overhead line are supplied by inductive energy harvesting from the overhead line, i.e. the energy of a few milliwatts required to operate the sensor module is converted by induction from the magnetic field surrounding the conductor cable into an electrical voltage in a coil. This means that the sensor system is not dependent on batteries and their regular replacement. The realized dynamic range of the energy harvester covers the current range commonly used in distribution and transport grids. The energy harvester also survives short circuits, which can reach several 10 kA of current. The sensor modules are mounted with so-called hotsticks directly on the current- and voltage-carrying overhead line, thus enabling uninterrupted operation of the line.

The use of a low-power wide-area-radio-network standard enables high transmission ranges even without the presence of mobile radio network coverage.

Since the second quarter of 2019, the prototypes have been tested by Heimdall Power AS in pilot customers' application environments as part of the development project. In the future, further versions with different operating parameters and functions are conceivable to make condition monitoring on high-voltage overhead lines even more effective and informative. The data collected during operation can not only be used for direct condition monitoring, but also serve as a source of information when planning new networks and expanding existing grids.

Our customer Heimdall Power AS received the award as one of the top three "Gamechanging Cleantech Nordic Startups by Cleantech Nordic" in May 2018 and the award as one of the top 100 "Global Cleantech Company by the Cleantech Group" in January 2019.