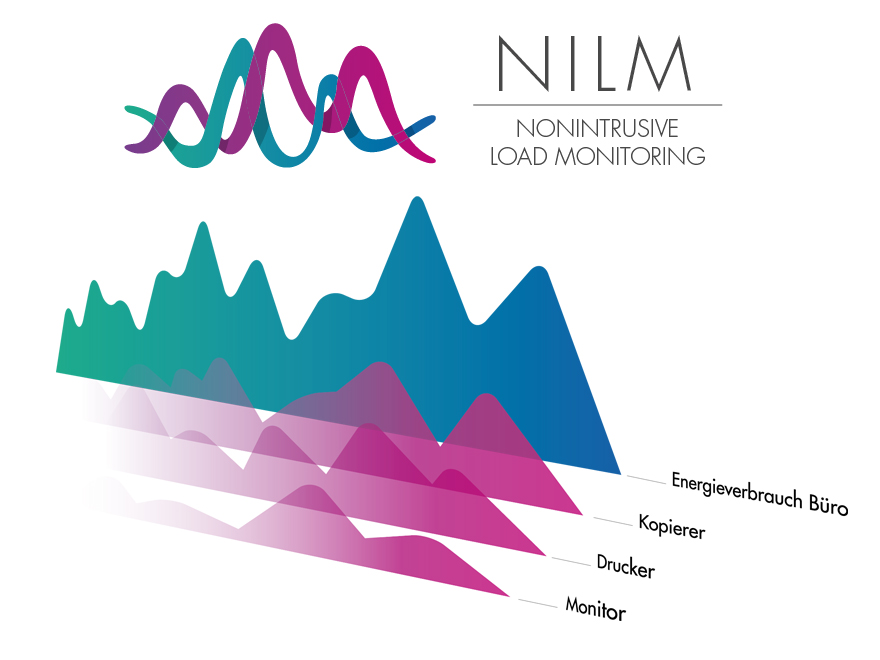

Energy and management and saving efforts have been impeding in the past, because the cause of increased energy consumption couldn’t be derived directly from the total consumption. . Identifying device-specific energy-saving measures and irregularities in the operation: That is the core idea of Nonintrusive Load Monitoring, in short NILM. Under the leadership of Fraunhofer IMS the partners developed an energy management system that enables the analysis of the device-specific power consumption with only one measuring point – a cost-effective alternative to submetering. With complex algorithms and machine learning processes the consumption patterns of devices are broken down from the total power consumption.

The fingerprint in the power grid

Every device affects the current and voltage in its own characteristic way. Through this fingerprint in the power grid, which is detected by Nonintrusive Load Monitoring, it is possible to break down the total power consumption into individual devices.

Condition monitoring: Detecting anomalies

A situation everyone is familiar with: You’re leaving the building and believe everything is switched off. But have you really thought of everything? With device-specific consumption analyses through Nonintrusive Load Monitoring deviations from the typical consumption pattern are identified for each device individually – without complex search for causes. In combination with event and time-based alarms that are sent directly after the occurrence of a deviation and therefore making it possible to take measures early on.

Predictive Maintenance: Detect necessary maintenance early

Whether the in-house plants and devices are working within normal parameters or a failure is threating to happen is of great economic importance in the context of industry 4.0. Misconduct is showing up first in the device-specific consumption pattern and later in changes in the overall consumption. For example, if the spectrum of the emitted interference of a compressor in normal operation changes, imminent loss of production can be prevented by timely intervention with countermeasures. The alarmed employees can examine the cause for misconduct at an early stage: Is there an operating error? Are there misadjustments? Is the compressor defected? In addition cost-intensive peak loads can be prevented by early corrective action.

Improving cost calculation, identifying saving potentials

Individual devices can be assigned to specific processes or applications, because of their use or the installation site. For example, in an industrial company there can be one compressor and two motors assigned to the process of refinement, but five compressors and one drive assigned to the process of manufacture. In food service the coffee machine and the cash register can be assigned to the sales area and the dish washer to the kitchen. With device-specific consumption analysis the devices can be classified and be assigned to processes and application areas, respectively. This way costs can be split and compared according to source and processes or applications can be analyzed holistically. Efficiency measures are not targeted towards the replacement of individual, inefficient devices, but towards energetic optimization of the whole process or application area with the corresponding equipment fleet.

Present results of NILM

Within the framework of the research project NILM, municipal companies and industrial companies as well as branches for examination have been acquired, because they offer great savings potentials due to their amount of pumps, electrical drives, heating and air condition systems. With the measurement technology installed by the companies several thousand measurements per second have been taken and the measured data has been analyzed and the power consumption of devices and plants has been determined. This data is the basis for the development for the highly complex NILM algorithm.

Apart from the complex algorithms a very powerful smart meter has been developed as a prototype which measures 8,000 high frequency measurement points (current and voltage) per second. Due to this resolution the prototype is able to detect even the smallest changes in the overall power consumption and assign them to individual devices. The first version of these NILM algorithms has already been tested in 2016. These have been continually developed by means of the high resolution data from the test measurements with the aid of machine learning processes for pattern recognition. In addition to the impact of the effective power the impact of the reactive power, apparent power and harmonics have been examined for the detection quality for optimization of the algorithms. Through the constant control of the results of the algorithms with the real subweighing operations (Ground Truth) the highest possible detection quality can be guaranteed. Within the energy management software the detection results of the algorithms can be analyzed more in-depth. The modular software solution is individually adapting to the user’s needs – from industry, trade and commerce. Extensive analytical tools support them in the identification, evaluation and monitoring of device-specific efficiency measures. With load and spectral analyses the peak loads can be detected on a single device level and optimization potentials can be derived to smooth the load curve permanently and to save costs with a steady supply by the energy provider. With the use of alarms plants, drives, devices etc. can be monitored. With notifications in real time additional costs through incorrect settings and malfunctions can be avoided. That way orders can be calculated more precisely and energy saving potentials can be detected through the assignment of energy costs to individual machines, areas or processes.

Publications

PhD Thesis Timo Bernard

University of Duisburg-Essen. Dissertation Title: Non-Intrusive Load Monitoring (NILM): Combining multiple distinct Electrical Features and Unsupervised Machine Learning Techniques.

29th May – 1st June 2018

2018 International Conference on Smart Grid and Clean Energy Technologies. Venue: Kuala Lumpur, Malaysia – IEEE, Universiti Tunku Abdul Rahman. Paper: Non-Intrusive Load Monitoring (NILM): Unsupervised Machine Learning and Feature Fusion, Timo Bernard, Martin Verbunt, Thorsten Wellmann, Gerd vom Bögel (Fraunhofer IMS)

6th – 7th November 2017

NILM.eu 2017 Workshop. Venue: London, UK. Paper: High frequency NILM in commercial and industrial settings, Gunnar Hoffmann, Timo Bernard, Martin Verbunt (Fraunhofer IMS).

14th – 15th May 2016

NILM2016 – 3rd International Workshop on Non-Intrusive Load Monitoring. Venue: Vancouver, Kanada – Simon Fraser University. Paper & Poster presentation: Analyzing 100 Billion Measurements: A NILM Architecture for Production Environments, Nikolaus Starzacher, Philipp Weidmann (Discovergy GmbH).

14th – 15th May 2016

NILM2016 – 3rd International Workshop on Non-Intrusive Load Monitoring. Venue: Vancouver, Kanada – Simon Fraser University. Paper: Unsupervised Learning Algorithm using multiple Electrical Low and High Frequency Features for the task of Load Disaggregation, Timo Bernard, Michael Marx (Fraunhofer IMS).

28th – 29th October 2015

Energie&Technik Smart Home & Metering Summit 2015. Venue: conference room München. Presented paper: NILM (NONINTRUSIVE LOAD MONITORING) – Gerätespezifische Stromverbrauchsanalyse für Smart Meter Lösungen, Timo Bernard, Burkhard Heidemann (Fraunhofer IMS).

20th – 23th October 2015

International Conference on Smart Grid and Clean Energy Technologies (ICSGCE 2015) – Sponsor: IEEE & VDE. Venue: Hochschule Offenburg. Presented paper: Combining Several Distinct Electrical Features to Enhance Nonintrusive Load Monitoring, Timo Bernard, Julian Klaaßen, Daniel Wohland, Gerd vom Bögel (Fraunhofer IMS).

Sponsored by

Partners

- Fraunhofer IMS (consortium leadership)

- Innogy SE

- EasyMeter GmbH

- GreenPocket GmbH

- Discovergy GmbH