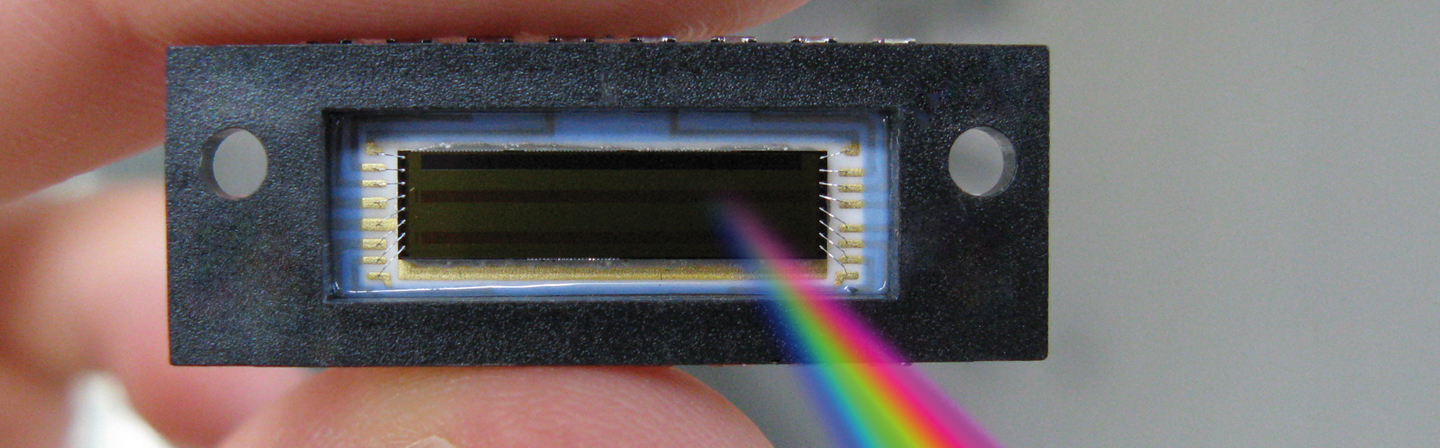

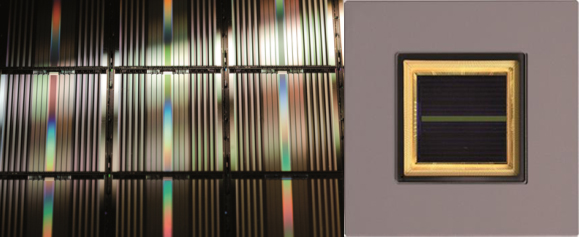

World record – Line sensor with extremely high record and read out speed

The 60-line high speed sensor is twice as fast as currently available solutions and delivers high quality images in a very high resolution. The high speed sensor detects, for example, banknote sheets– almost like a scanner – line per line, when they get out of the printing press. It records 200,000 color images per second with an exposure time of a few millionths of a second. A software compares the images with the target image and identifies the banknote with faulty security features. To reach the high speed, Fraunhofer IMS has integrated an individual readout chain per pixel column. In addition, special pixels were developed that are able to work with conventional optics despite the short exposure times. In every pixel column the three colors red, green and blue are equally detected over the whole pixel area. This results in a high quality color reproduction. Another feature of the sensor: the high number of lines enables the detection of objects from different angles, which can be used to test surface structures in 3D, like tilting effects of holograms. The special architecture of the sensor opens up new room for a variety of applications. Due to the high number of lines, the wavelength spectrum is expendable up to the UV and infrared range. With the ability to also analyze 3D surfaces, the high speed sensor is suitable for quality control of different materials in the industrial production. Another application area is the evaluation of tracks and contact wires of trains. Even at a speed of 300 km/h the high speed sensor is able to produce pin sharp images with a resolution of up to 0.4 mm and therefore detect hairline cracking. Near earth satellites that are equipped with such a sensor and orbit the earth at a speed of 26,000 km per hour can record color images of the earth’s surface with a resolution of three centimeters.