High-precision Triangulation

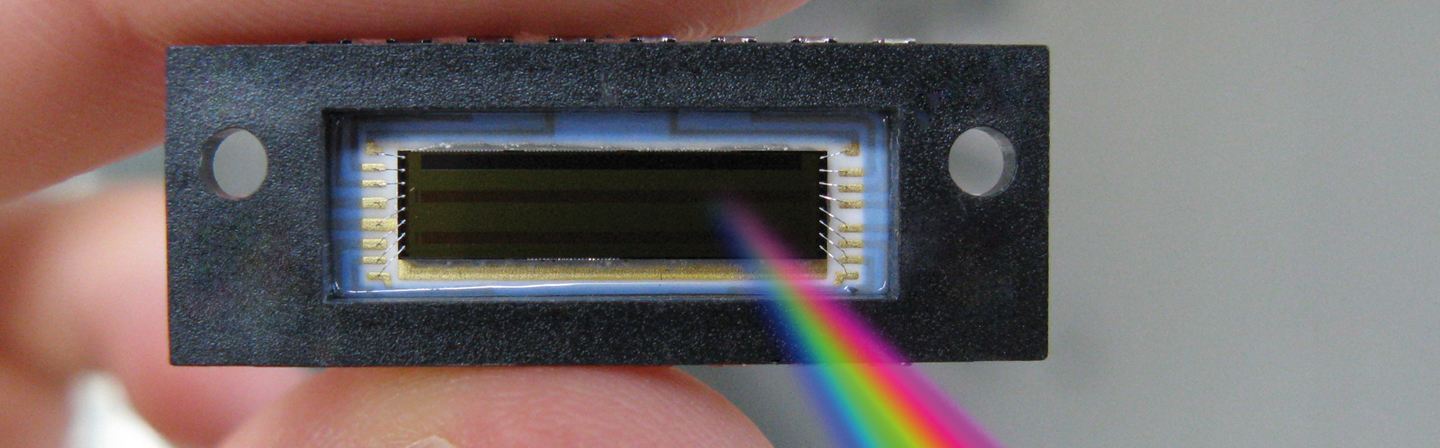

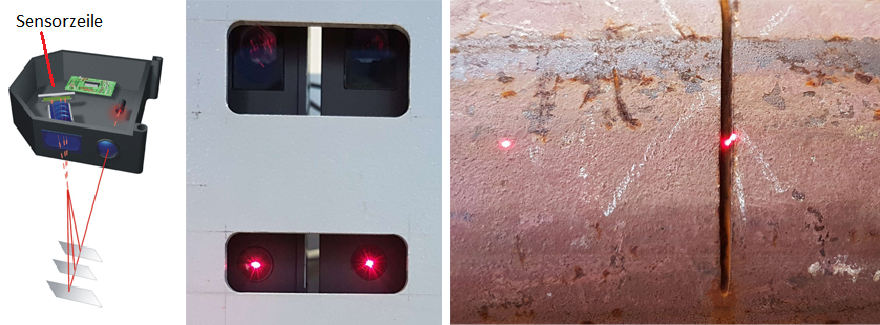

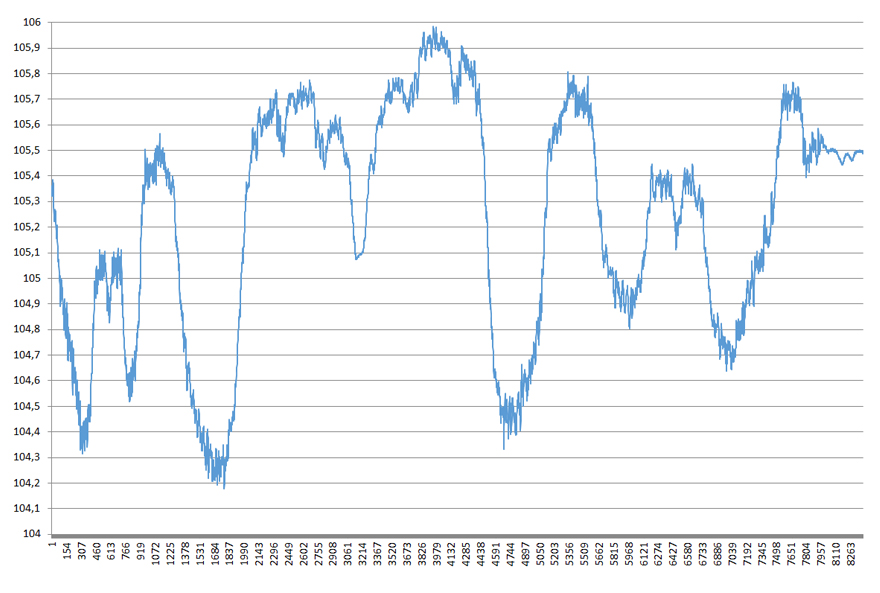

Since the 80s fast and highly precise systems based on the principle of laser triangulation have been used for the measurement of objects. A laser point or laser line is projected onto the measurement object and the reflected light hits on different positions, depending on the distance, on a line or surface sensor, which allows for the reconstruction of the distance to the measurement object. For example, welding seams can be monitored during the production process, surfaces can be checked for planarity or the tread depth of tyres can be monitored using this technology. These laser triangulation systems deliver a high measurement precision in the 1 µm area and a comparably high measurement speed of up to 50 kHz. Currently available triangulation sensors contain off-the-shelf sensors (PSDs or CMOS- and/or CCD sensor lines) as detector elements. With this solution the limits are often reached during the modern production processes with regard to sensitivity and speed.

Fraunhofer IMS has performance-optimized photo detectors and highly integrated sensor ICs in its portfolio which detect a high overexposure within a few microseconds and have an ambient light suppression of 50 klux. Apart from that, the sensors of Fraunhofer IMS for the industrial measuring technology show a significantly increased measuring speed of 100 kHz with a sensitivity of up to 500 V/μJcm2 (doubling of the state of the art technology).

The Fraunhofer IMS sensors for the industrial measurement technology are based on newly in-house developed and patented pixel structures that can be manufactured in a standard CMOS process. With these pixel structures it is possible on the one hand, to detect temporally resolved signals through fast electronic shutters and, on the other hand, to reach a very high sensitivity. The latter is necessary, because there is correspondingly less light available per measurement with increasing measurement speed. Fraunhofer IMS has been working in the area of CMOS image sensor systems for over 25 years and has the possibility to realize new components for the industrial measurement technology through the close cooperation of image sensor technology development.