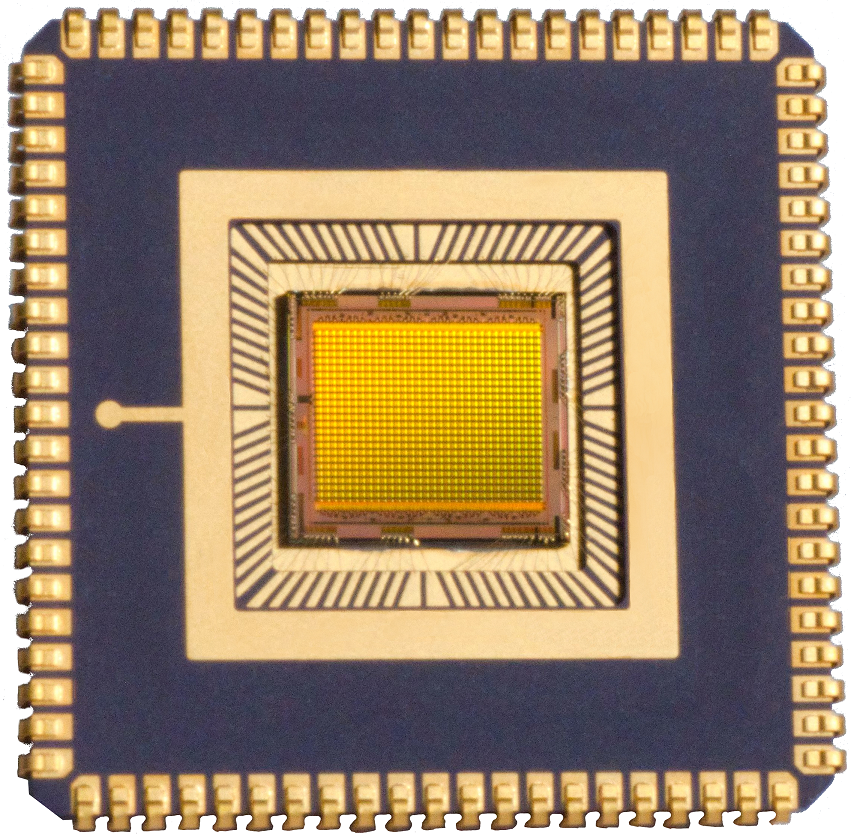

In sensor technology, maximum miniaturization is achieved if sensor elements can be integrated with the signal-processing electronics on a single silicon chip. There are various ways to achieve this. On the one hand, physical effects in the silicon itself can be exploited, e.g. temperature dependencies or optical effects or the deflection of charge carriers by magnetic fields. On the other hand, however, additional processing steps or additionally applied layers can be used to generate a sensor effect, e.g. piezoelectric layers. For both types of sensors, examples are shown below which have already been successfully implemented in integrated sensor systems.

Examples of integrated sensors based on physical effects in silicon start with the circuit components. Many parameters of the integrated components are temperature-dependent, which often has to be compensated in order to obtain temperature-stable circuits. However, one can also use these effects to realize a good temperature measurement with the parameter change. A temperature measurement via the forward voltage of diodes, which are poled in forward direction, has become generally accepted. The resulting voltage is based on the bandgap voltage of the material, in this case silicon, and delivers accuracies of a few tenths of a degree when calibrated.

Furthermore, magnetic fields can be exploited by using the Hall effect in current-carrying conductors on a chip. This effect is independent of the material and is based only on the deflection of charge carriers in the magnetic field.

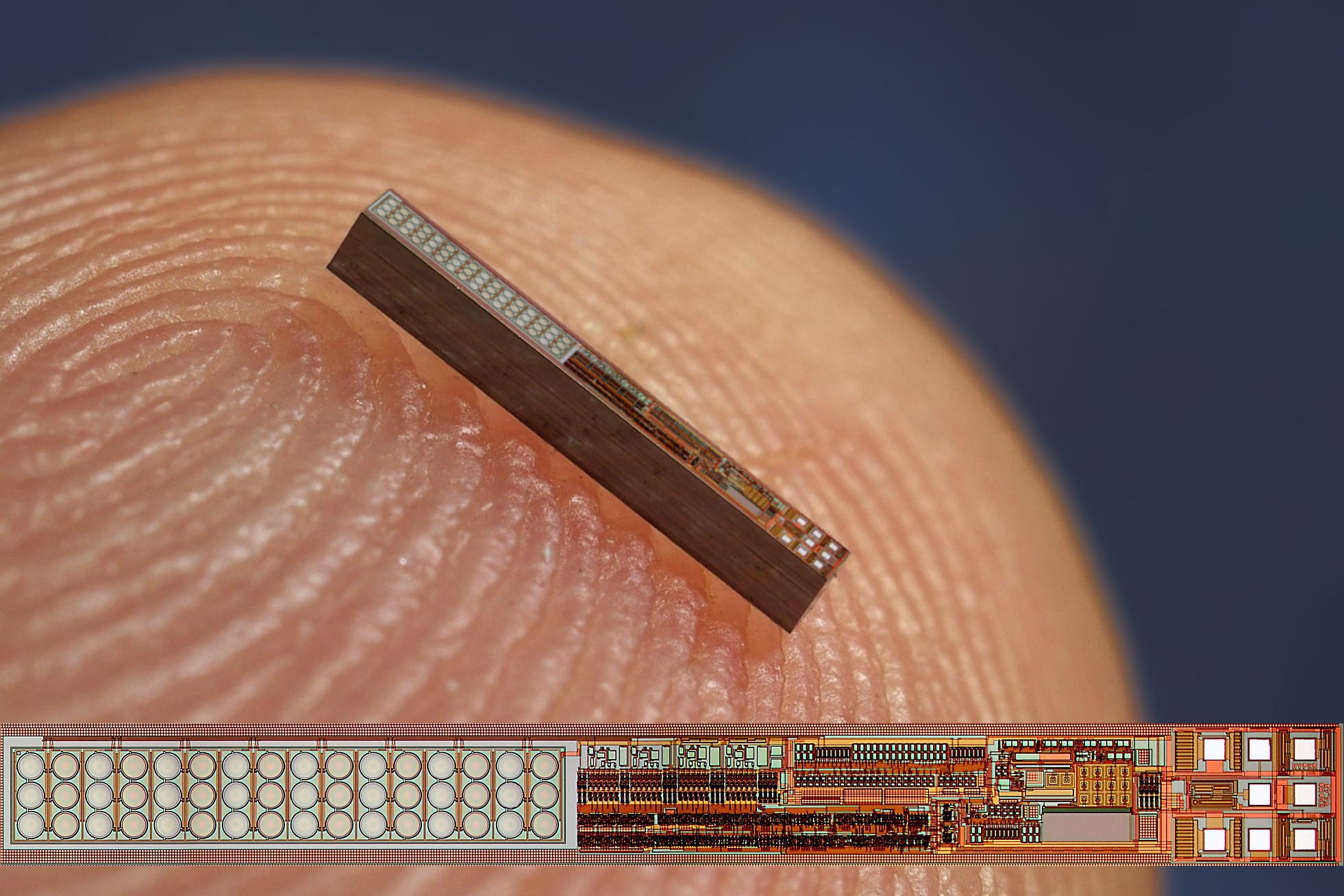

Optical sensors, which can detect light according to various principles, represent a broad field within integrated sensors. Photodiodes have become established at Fraunhofer IMS, which are capable of detecting individual photons, for example as single photon avalanche diodes. A multitude of optical detection technologies is based on this basic principle. More info.

Further sensing effects in integrated sensors can be realized by additional layers on the silicon. This is often combined with mechanical structuring of the silicon by etching processes, e.g. to obtain cavities. This opens up a wide range of new applications. Examples are integrated pressure sensors, acceleration and vibration sensors based on freely suspended moving masses. A new field of activity at Fraunhofer IMS is to use bioactive layers to specifically detect biological substances.