First implementation project completed

KIMETRO project completed: progress in the automated processing of metal tubes

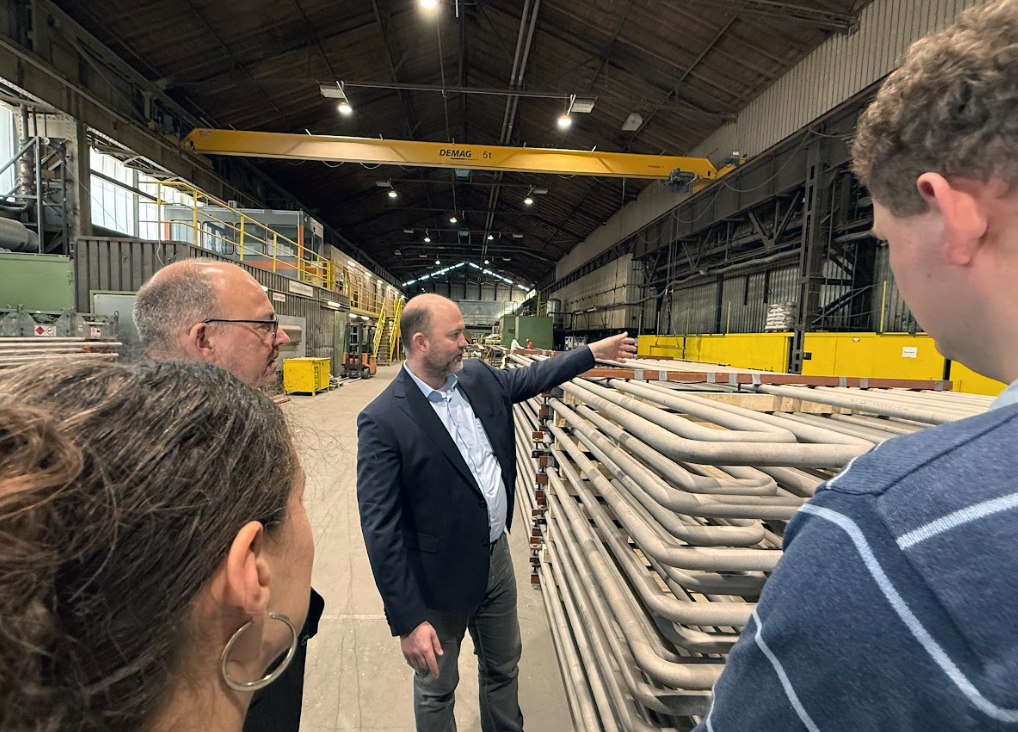

Duisburg, March 7, 2025 - Successful completion: With a meeting of the ZaKI.D project team and the company Häuser & Co. GmbH on March 7, 2025, the first implementation project KIMETRO of the Center for Applied Artificial Intelligence (ZaKI.D) was successfully completed. The team, led by Ole Werger, made significant progress in the automated processing of metal pipes using artificial intelligence (AI).

The Center for Applied Artificial Intelligence Duisburg (ZaKI.D) has set itself the goal of integrating advanced AI technologies into industrial practice and thus increasing the competitiveness of local companies in and around Duisburg. This knowledge transfer is to be achieved in various implementation projects. The first project was completed on Friday, March 7, 2025.

The objective of KIMETRO

In the »KIMETRO« (AI-supported METallROhr-Beschichtung) project, a feasibility study was conducted to determine the optimal temperature and duration of heat supply on different metal pipes using AI. Currently, employees assess the optimal processing temperature based on a specific gloss of the pipe surface.

In the future, a camera-based system will analyze this gloss and automate the metal pipe processing. To this end, various machine learning algorithms have been implemented and evaluated that use the camera images as a data source to determine the optimal processing parameters for the workpiece in real time if possible. This ensures that the pipes are produced with consistent quality – comparable to an inspection by a specialist.

Future prospects: welding robotics and new material applications

In the medium term, the technology should be used to relieve the few available skilled workers. During the project, numerous image series were taken and analyzed during processing. »The project results form a solid basis for future applications in automated production, for example for the use of machine welding robots,« says research associate and KIMETRO project manager Ole Werger.

The developed model also covers a wide range of materials, which significantly expands the technology's applicability. »In the future, AI technology could even be better than the human eye and thus form the basis for developing and processing new material alloys. The boundaries of technical feasibility are being pushed,« adds CEO Hendrik Häuser.

The successfully completed project, which was initiated by ZaKI.D project manager Prof. Torben Weis from the University of Duisburg-Essen and Andree Schäfer from Duisburg Business & Innovation GmbH, is now to serve as a »model« for future implementation projects within the ZaKI.D project. »We are convinced that the combination of human expertise and artificial intelligence will shape the future of industrial manufacturing,« adds Werger.

About ZaKI.D

The Center for Applied Artificial Intelligence Duisburg (ZaKI.D) is a pioneering project of the city of Duisburg. It was the first project in the so called 5-StandorteProgramm to receive funding of approximately 18 million euros from the Federal Ministry for Economic Affairs and Climate Protection (BMWiK) and the Ministry for Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia (MWIKE). The project focuses on using artificial intelligence (AI) on very small devices such as sensors. This helps to avoid data protection issues, conserve valuable resources and offer new services directly in devices or machines. The aim is to help small and medium-sized companies in the region to integrate AI into their operations and products.

The Fraunhofer Institute for Microelectronic Circuits and Systems IMS, the University of Duisburg-Essen and KROHNE Messtechnik GmbH are working together on the project. The city of Duisburg is an associated partner.