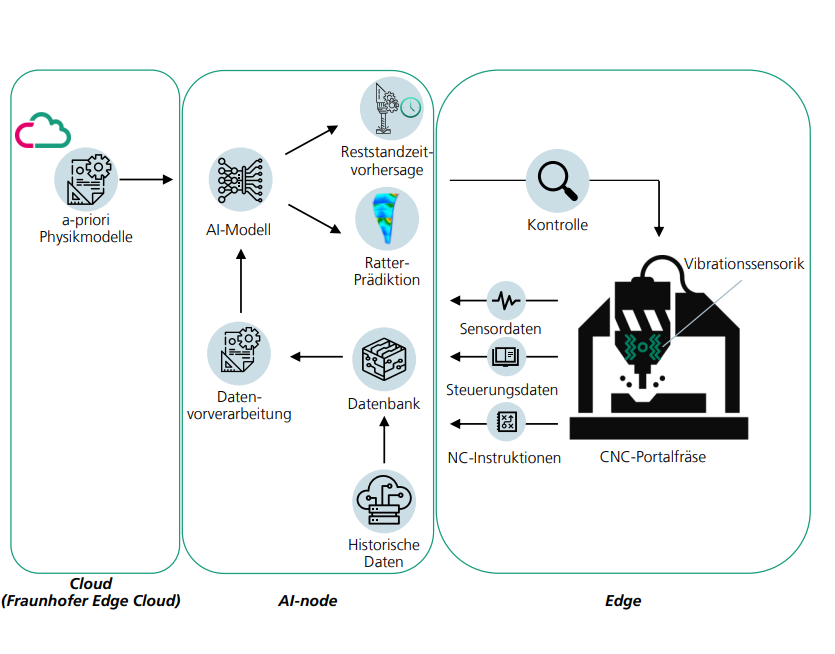

In the demonstrator, various AI and ML algorithms for condition monitoring were implemented to optimize the efficiency and reliability of the machining process. Initially, condition detection and prediction of the remaining tool life of a portal milling machine on-site are performed using ML models. Additionally, other system states are detected, such as active machining, the condition of certain components, and surface quality, due to detection of the occurrence of chatter.

A key aspect was the faster adaptation of training to new machine configurations, in this case, the portal milling machine, through the use of transfer learning. Additionally, Auto-ML methods were tested and applied to automate and accelerate model development.

The optimization of AI models was particularly emphasized for small, mobile, and energy-efficient systems.

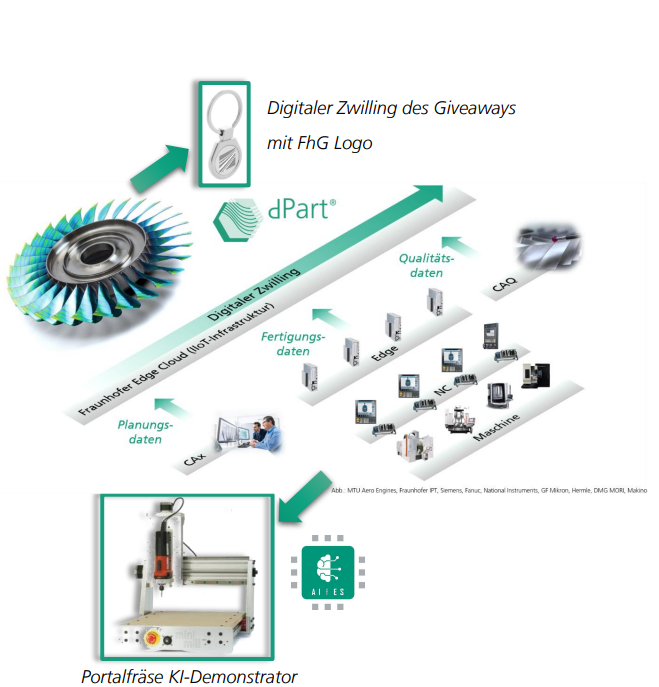

Another goal was the development of a physics-based simulation model as a digital twin on the Fraunhofer Edge Cloud for the detection of chatter, which serves as real-time detection of surface quality during the machining process.