Sensor for the measurement of intraocular pressure

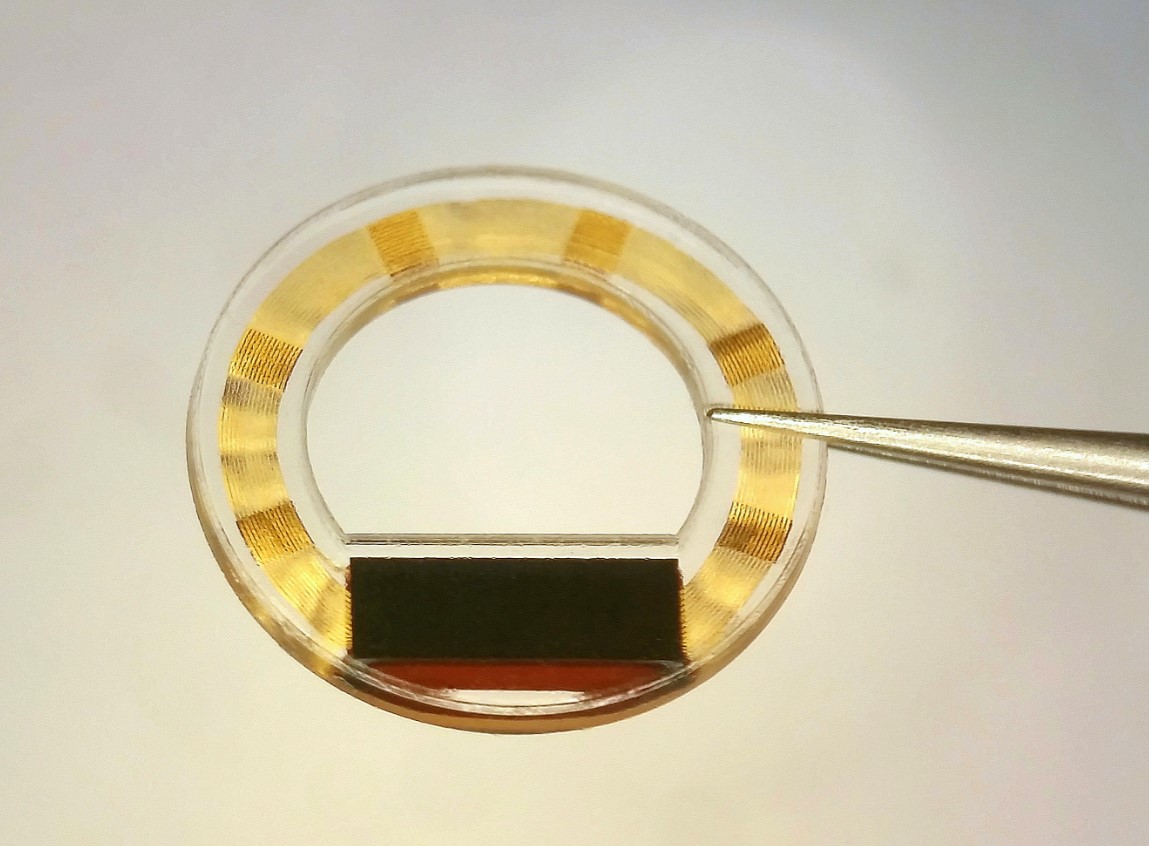

A sensor implant enables an optimal therapy by comfortably recording the temporal course of the intraocular pressure.

The eye constantly produces new aqueous liquid. If the amount is greater than that of the outflowing fluid, the intraocular pressure rises. In the long run, too high intraocular pressure leads to irreversible damage and the death of the optic nerve. This disease is called glaucoma. In order to prevent the disease from progressing, it is necessary to adjust the intraocular pressure to the normal range, e.g. with medication.

Knowing the level of intraocular pressure and how it changes over time is crucial for successful treatment. Tonometry is currently a common method of measuring intraocular pressure, but it is usually carried out at too long intervals by the doctor, so that the data basis on the course of pressure in the eye is too small. Furthermore, it must be assumed that dangerous peak values, which can occur several times during the course of the day, are not recorded.

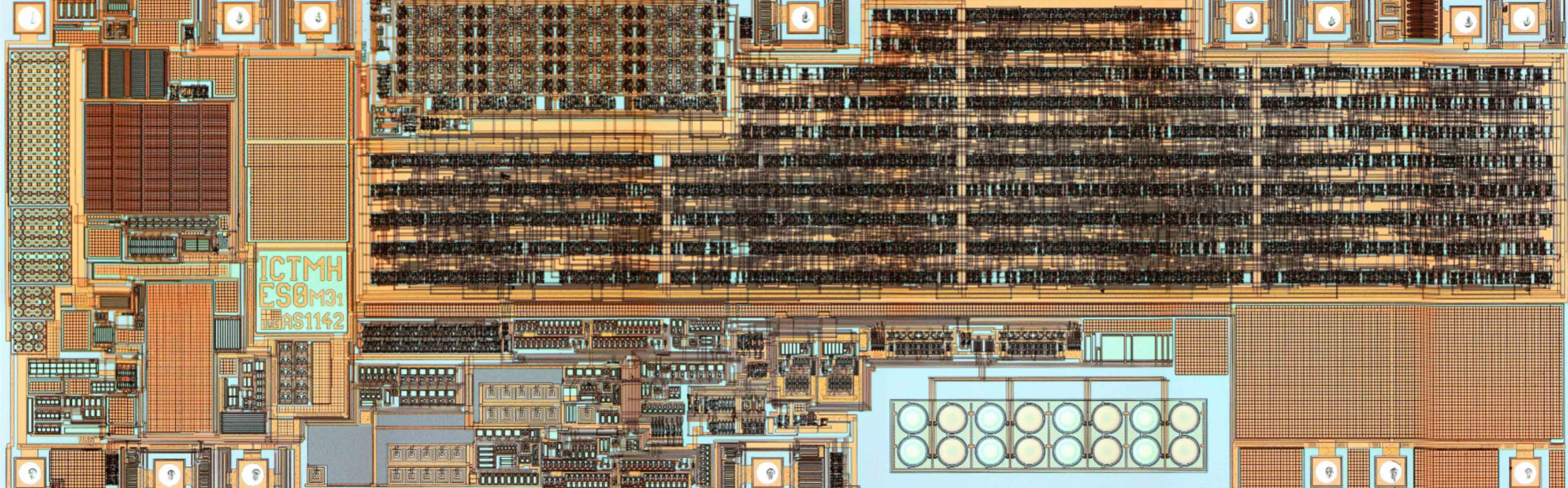

With the EYEMATE sensor system, which was developed by the company Implandata Ophthalmic Products GmbH from Hannover in cooperation with the Fraunhofer IMS, this restriction no longer applies. With the Intraocular pressure sensor, a non-contact measurement can be carried out independently by the patient within a few seconds. The more often the patient reaches for the reader, the more meaningful his pressure readings are for the attending physician.

In an operation, the eye is opened with a small incision, the clouded human lens is removed and replaced with an artificial lens. Since the artificial lens takes up less space in the eye than the natural one, the intraocular pressure sensor can be inserted in the freed-up area.