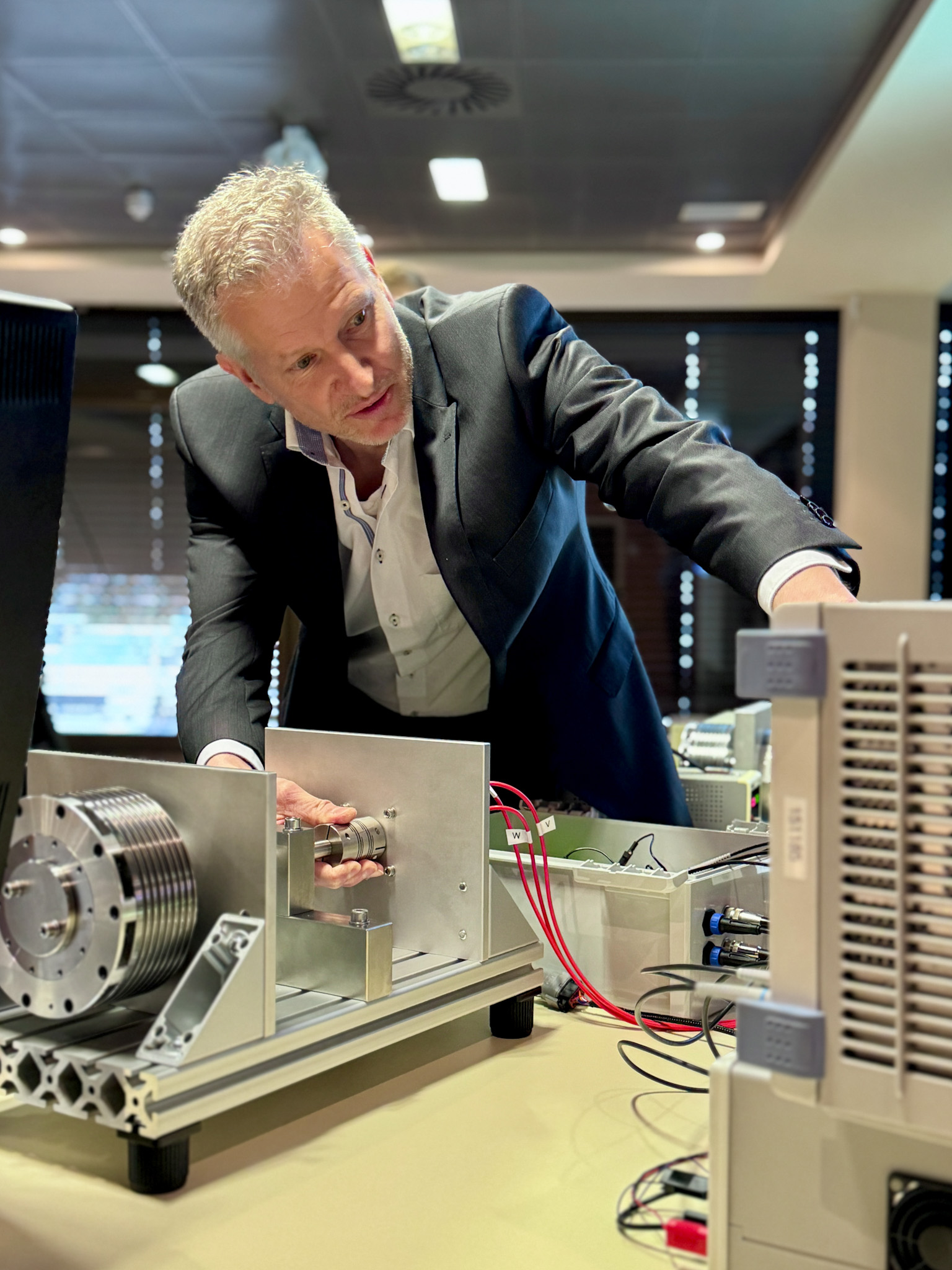

Prototype for intelligent e-drives in industry

Fraunhofer IMS presents PowerCare: AI for intelligent e-drives

Duisburg, February 24, 2025 - An important milestone in the PowerCare project: the prototype for intelligent e-drives in industry was presented for the first time at the third advisory board meeting at the Fraunhofer Institute for Microelectronic Circuits and Systems. The innovative system is intended to enable real-time health monitoring of electric motors and thus help to prevent failures and increase energy efficiency.

“After 1.5 years of highly innovative, but also high-risk development work, we can make the leap into industry with this prototype and further optimize electrification and automation, avoid failures and save electricity,” explains Alexander Stanitzki, Head of the Industry business unit at Fraunhofer IMS.

AI-supported real-time analysis for maximum reliability

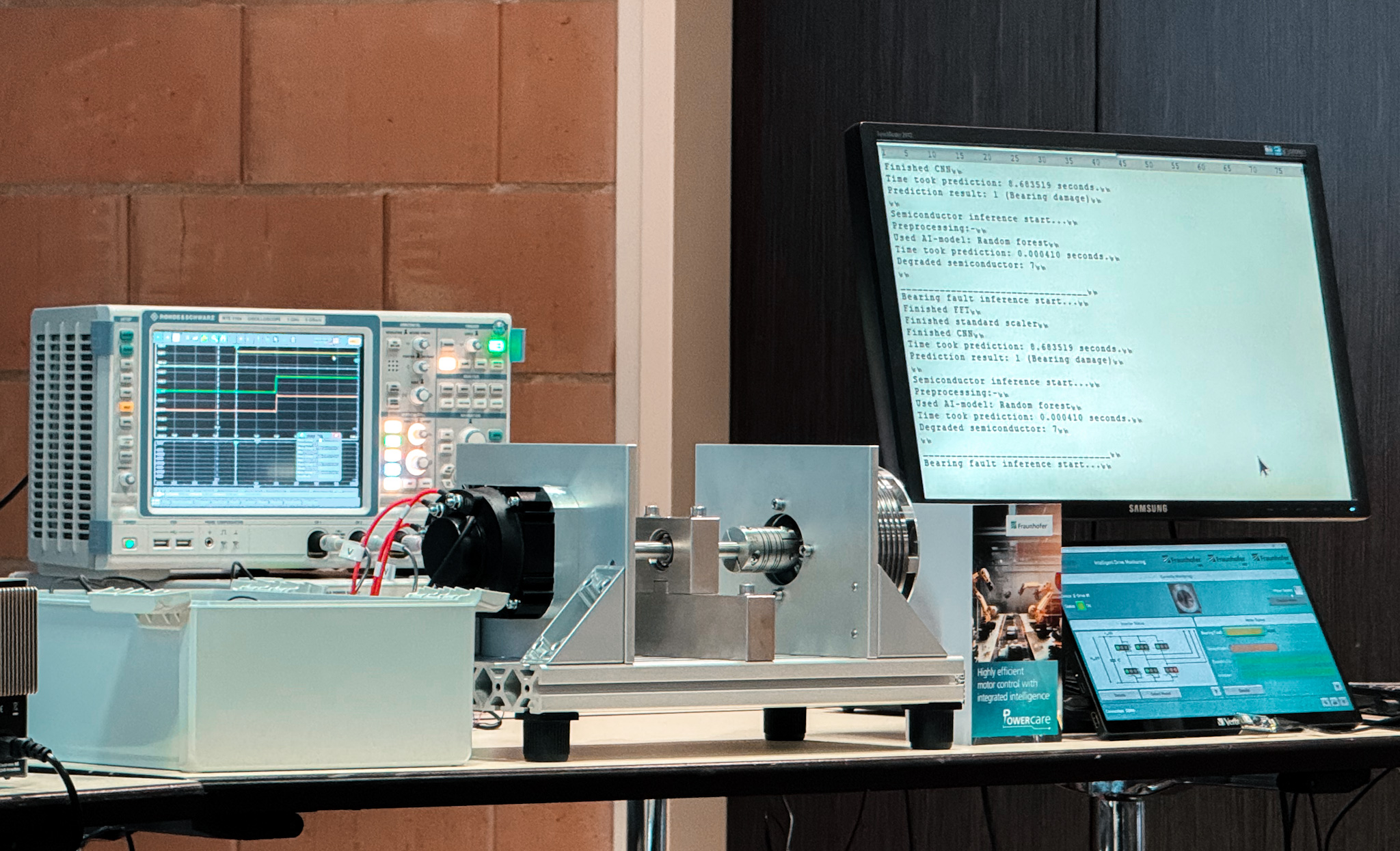

The PowerCare prototype combines state-of-the-art gallium nitride (GaN) power semiconductors with embedded AI to monitor motor controls in real time. This intelligent technology boosts the efficiency of electric motors and increases their reliability. An innovative PWM (Pulse Width Modulation) controller with embedded AI continuously analyzes the status of the electronics and motor mechanics. This allows potential failures to be detected at an early stage and prevented through timely maintenance.

Challenge: real data for practical AI training

One of the biggest challenges in the project is adapting the AI models to real operating conditions. As the operating data for industrial drives can be read directly from the power electronics, no additional sensor technology is required. This operating data, for example on bearing damage and the wear of GaN semiconductors, makes it possible to further train and optimize the algorithms. This so-called “mission profile” ensures that the AI also works precisely under real conditions.

Outlook: Two platforms for industrial tests by 2026

Two test platforms will be set up by April 2026 to test the results under realistic conditions:

- Demo case: a portable plug-and-play test environment for industrial customers. Here, companies can test the reliability of their specific applications - such as conveyor belts, pumps or drone motors - using PowerCare technology.

- Industrial motor test bench at Fraunhofer IISB: Here, the efficiency and integration of the innovative vertical gallium nitride semiconductors (vGaN) in a drive converter are tested under realistic industrial conditions.

The PowerCare project shows how intelligent technologies can drive electrification in industry and save resources at the same time. The successful prototype lays an important foundation for further transfer into practice.

The PowerCare project is funded as part of the Fraunhofer-Gesellschaft's internal programs, grant number PREPARE 40-06175.

Fraunhofer IMS

Shaping a safe and sustainable future with intelligent sensor systems: Fraunhofer IMS works on innovative microelectronic solutions with over 200 talented scientific staff and students in numerous state-of-the-art research laboratories.

As a reliable research and development partner for industry, the institute aims to develop customized sensor technology for your specific requirements in the fields of biomedical sensors, optical systems, open-source semiconductors, embedded AI, technology services and even quantum technology. The teams in the four business units - Health, Industry, Mobility and Space and Security - are committed to implementing outstanding and versatile microelectronics in all their projects. These solutions are characterized by high integration capability, enormous energy efficiency and reliable functionality even under harsh conditions.

The Fraunhofer IMS is a cooperating institute in the Research Fab Microelectronics Germany (FMD). In the FMD, 15 research institutes work together under one virtual roof.

www.ims.fraunhofer.de