RFID technology has successfully established itself in many areas. From simple tags for theft protection to permanent monitoring of operating variables in processes, RFID technology is used in a variety of ways. LF (Low Frequency), HF (High Frequency) and UHF (Ultra High Frequency) systems are widely used and cover a large part of the application areas. The use of RFID technology in metallic environments in industrial applications becomes problematic. Here, a distinction can be made between two scenarios:

- The transponder (tag) is located in a metallic environment, e.g. in a metallic container.

- The tag is attached directly to a metallic substrate.

Both cases have to contend with different difficulties. If reading the tags is difficult in the first case due to the formation of standing waves, the performance of the tag on metallic surfaces is particularly problematic in the second case. In addition, in many scenarios one is severely limited in the size of the tag. The tag must be applied to small surfaces and must not restrict the performance or handling of the wearer. Especially in tool tracking and sterile goods tracking, the high demands on a tag are clearly visible.

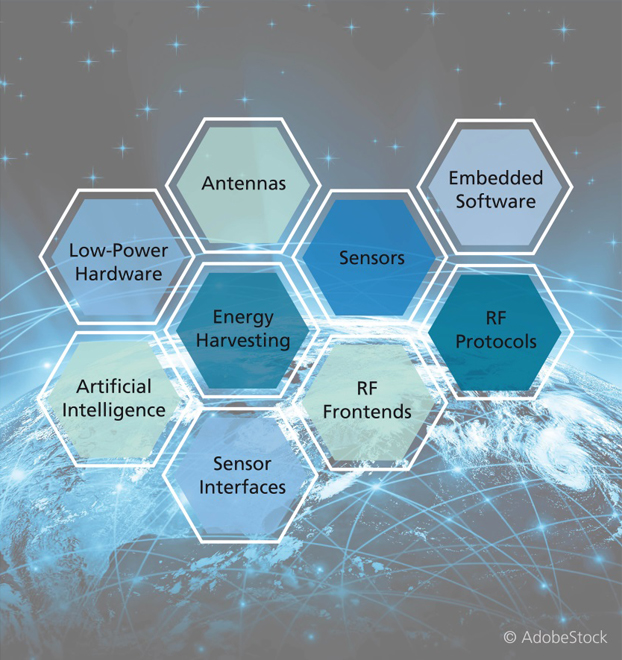

In this field, the Fraunhofer IMS is developing new RFID technologies that are suitable for use on or in metal (RFID in/on Metal). For this purpose, the SHF (Super High Frequency) range can be used for applications on metal and the LF range for applications in or behind metallic barriers in order to increase the performance of RFID tags on/in or behind metal. The use of the SHF range has many advantages over conventional and well-known RFID solutions with regard to the size of the RFID tag and, above all, the possible use in a metallic environment. So far, no RFID standard in the SHF range is available on the market. The Fraunhofer IMS is therefore also actively working on communication protocols for this range, from which a standard is to be developed later.

The RFID in/on Metal technology developed by Fraunhofer IMS includes the entire RFID system, from the reader to the transponder (tag). We support you in the specification of the system parameters, the conception as well as the realization. In doing so, a system is developed specifically for your needs and the antennas are adapted specifically for the respective environment.

SHF technology for RFID in/on metal has so far been used in the field of tool tracking. LF technology is used, for example, in combination with pressure sensors for wireless measurement of pressures inside vacuum insulation panels (VIP) and is being further developed in corresponding projects. Further information on application examples can be found in the following media box.