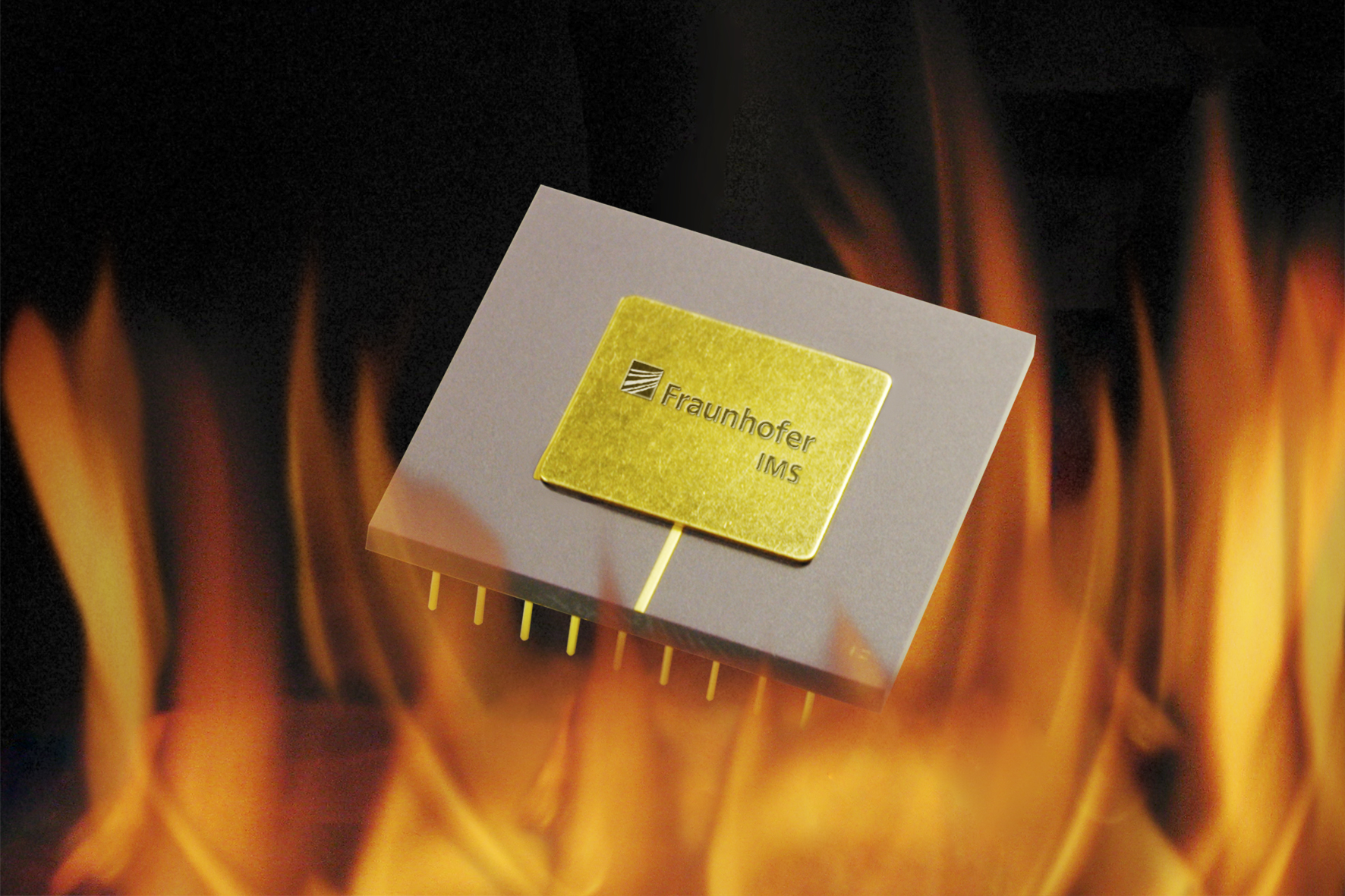

In the last years Fraunhofer IMS has established extensive know-how in various research and development projects to develop analog and digital circuit designs for the extended temperature range of -55 °C up to 300 °C. The following examples give an insight into the various possibilities of integrated high temperature electronics.

High Temperature Applications

Fraunhofer IMS could establish extensive know-how in various research and development projects to be able to offer solutions for nearly every circuitry problem even in the extended temperature range of up to 300 °C.

eHarsh

Sensors are key elements for the acquisition of the environmental characteristics and build the foundation for the intelligent control of industrial processes. Often the application of sensor systems is impossible, because the harsh environmental conditions of industrial processes, characterized by high operating temperatures, mechanical stress in form of pressure or vibration or wet or chemically aggressive surroundings, don’t allow for a reliable operation of electronic components. “eHarsh” has the goal to realize intelligent sensor systems especially for harsh environmental conditions. Within the framework of the project Fraunhofer IMS develops application-specific integrated circuits for implementation into these sensor systems. These are in particular a microcontroller as well as an analog sensor frontend with an integrated analog-digital converter for piezoresistive sensors.

This project is supported by the internal Fraunhofer program of lead projects.

HOTPROX

For the position detection of parts or machine positions in the industry there are different types of sensors applied. Inductive proximity switches have reached a high market share due to their robustness. In the past years a trend could be observed for the extension of the application area in the direction of higher temperatures to be able to use the switches in hotter areas, for examples in painting lines or drying ovens. Therefore a compact inductive high temperature proximity switch with completely integrated electronics has been developed in the project HOTPROX for the use in temperature ranges of -25 °C to +250 °C which is based from the smallest type (currently M8) up to the biggest type (currently M80) on one single concept. The component has been developed in the HT SOI CMOS technology (H035) of Fraunhofer IMS.

This project has been supported by the BMBF under the project number 16ES0324.

ADVICE

The project ADVICE (ADvancing user acceptance of general purpose hybridized Vehicles by Improved Cost and Efficiency) supported by the European Union contributes to the achievement of ambitious goals for exhaust gas reduction in the European area. For this purpose a variety of measures is implemented especially in hybrid vehicles which lead to energy savings under great consideration of the cost aspect. In ADVICE Fraunhofer IMS is developing strategies to increase the efficiency of electronic components through the use of high temperature electronics.

This project is supported by the program “Horizon 2020” of the European Union under the project number 724095.

E2COGaN

In the EU and BMBF cofinanced project E2COGaN (Energy Efficient Converters using GaN-Power Devices) Fraunhofer IMS has developed driver circuits for GaN power transistors which are particularly applied in converters for the transfer of energy. The result is a gate drive which is adapted to the special requirements of GaN power transistors and can be operated in temperatures of up to 250 °C.

This project has been supported by the Federal Ministry of Education and Research under the project number 16ES0020K and the research initiative Eniac of the European Union under the project number 324280.

HOTMOS

In the project HOTMOS Fraunhofer IMS and Carnot CEA-LETI cooperated to extend the application possibilities of microelectronics in harsh environments. In the project a SOI CMOS technology platform for microelectronic circuits has been developed which can operate in high temperatures of 250 °C and more. The main characteristics of this technology are:

- Characteristic size 0.35 µm

- Integration density: 8500 agtes/mm²

- Tungsten metal coating to avoid electromigration

- EEPROM memory (reading, writing and deleting are possible for the whole temperature range)

This project has been supported within the framework of the program Inter Carnot Fraunhofer by BMBF and ANR (Grant 03IO0804 / 01SF0804).

HOTDATA

In aeronautical engineering there is great potential in energy savings and cost reductions through an increase in efficiency of engines both in operation and their maintenance. However, there is a variety of operating parameters that need to be recorded directly on the engine which provide information on the current operating status and give indications on potentially necessary maintenance work. Fraunhofer IMS develops in the project HOTDATA of the aviation research program LuFO V of the Federal Ministry of Economics and Technology (BMWi) a high temperature resistant data concentrator which is designed as an interface between a variety of sensors on one side and a digital interface on the other side. This project is supported by the Federal Ministry of Economics and Technology under the project number 20X1713B.